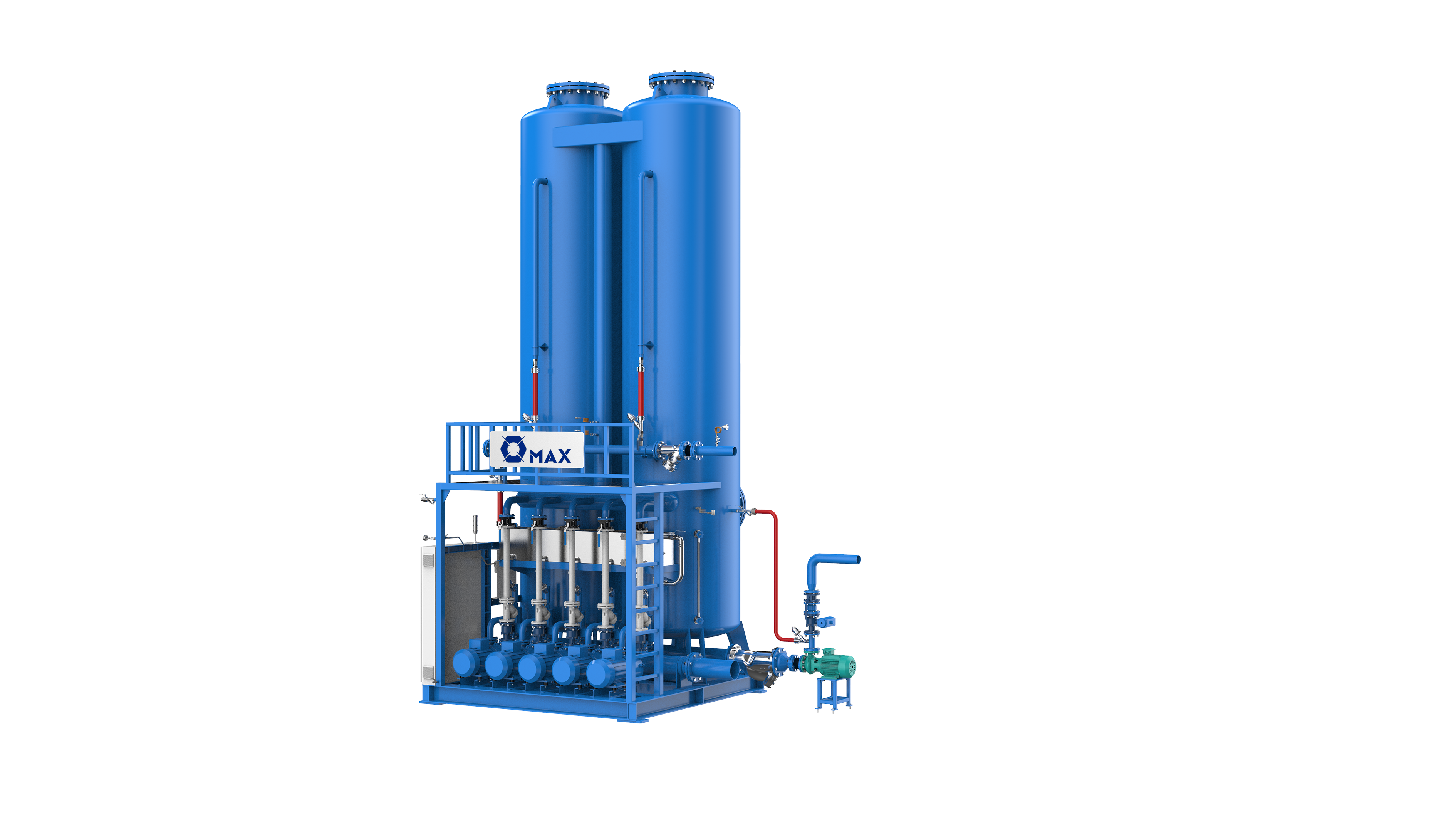

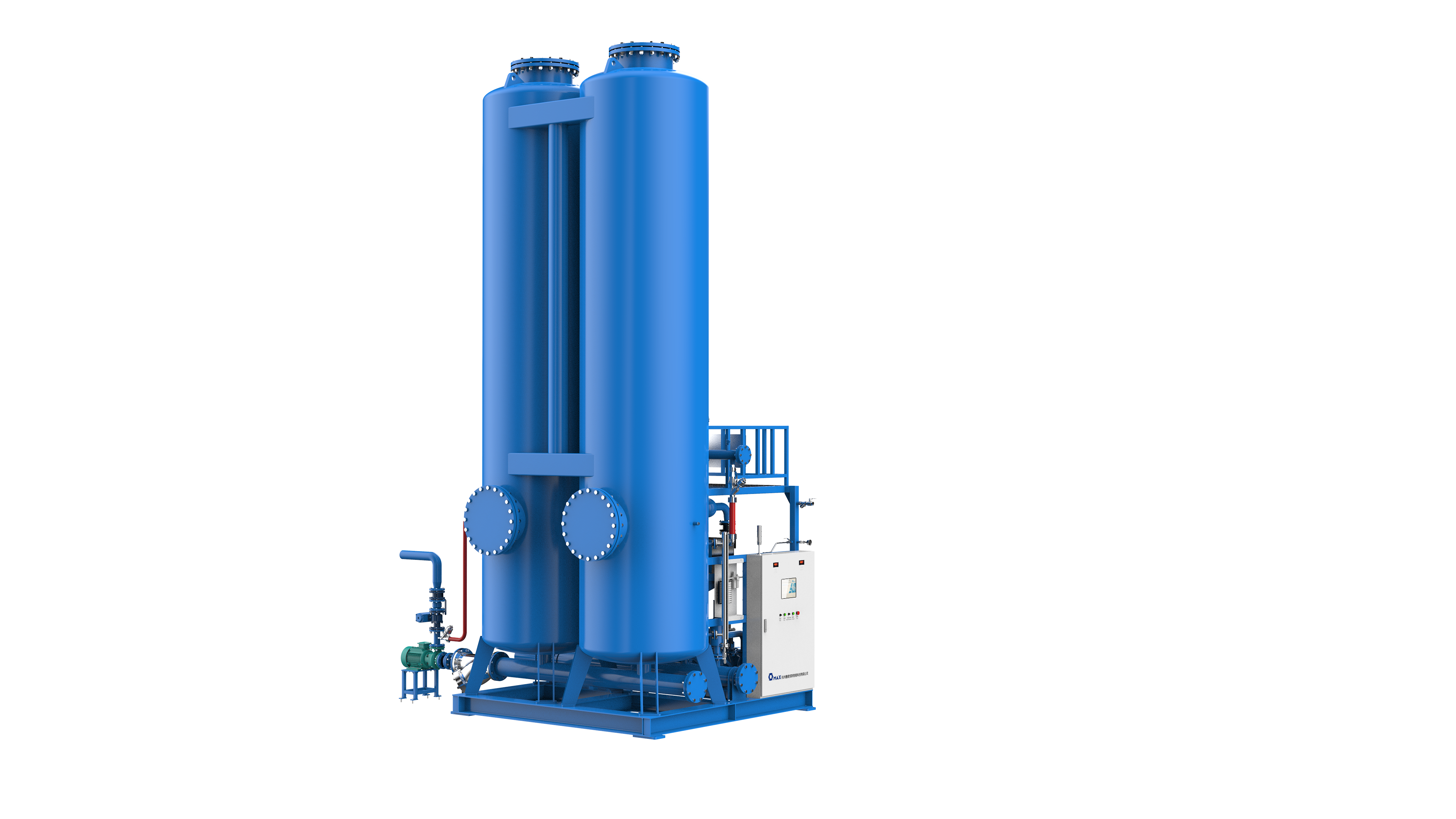

20m³ Vacuum Cooling System for EPS - Dongshan Machinery

Advanced EPS Foam Production Equipment

Maximize your foam production efficiency with our state-of-the-art EPS shape molding machine match. Designed with cutting-edge technology, this equipment offers numerous advantages for modern foam processing companies.

Compact and Efficient Design

- Integrated design for easy transportation and installation

- Small overall footprint saves valuable floor space

Durable Construction

- Constructed with low alloy steel for enhanced durability

- Barrel body welded with automated submerged arc welding for optimal strength

- Dual-coat painting with primer and topcoat for extended lifespan

Innovative Cooling and Pressure Control

- Stainless steel interior for rapid heat dissipation

- Electronic control for precise adjustment of water, air, and negative pressure

- High-performance vacuum pump unit from top-tier international brands

User-Friendly Interface

- Intuitive high-definition, 15-inch industrial computer LCD display

- Simple and efficient screen operations

- Remote control technical support available (optional)

Easy Maintenance

- Quick and thorough cleaning with a high-pressure water gun system

- PLC Modular Mitsubishi FX Series for reliable programmable control

- Motors equipped with overload and power-off protection switches

Specifications

- Bucket Capacity: 10 m³

- Water Pump: 5.5Kw

- Vacuum Pump: 11Kw

- Connection of Vacuum Pipe: DN600

- Overall Size: 3000 x 2900 x 7500 mm

- Weight: 10 Tons

Optimize your EPS/EPP foam production with our rapid mold change machine. By significantly reducing mold change time, it enhances production efficiency and is perfect for batch production of various foam products. Choose our equipment for its stability, energy-saving features, and labor cost reduction. It is your ideal partner for seamless and efficient manufacturing processes.