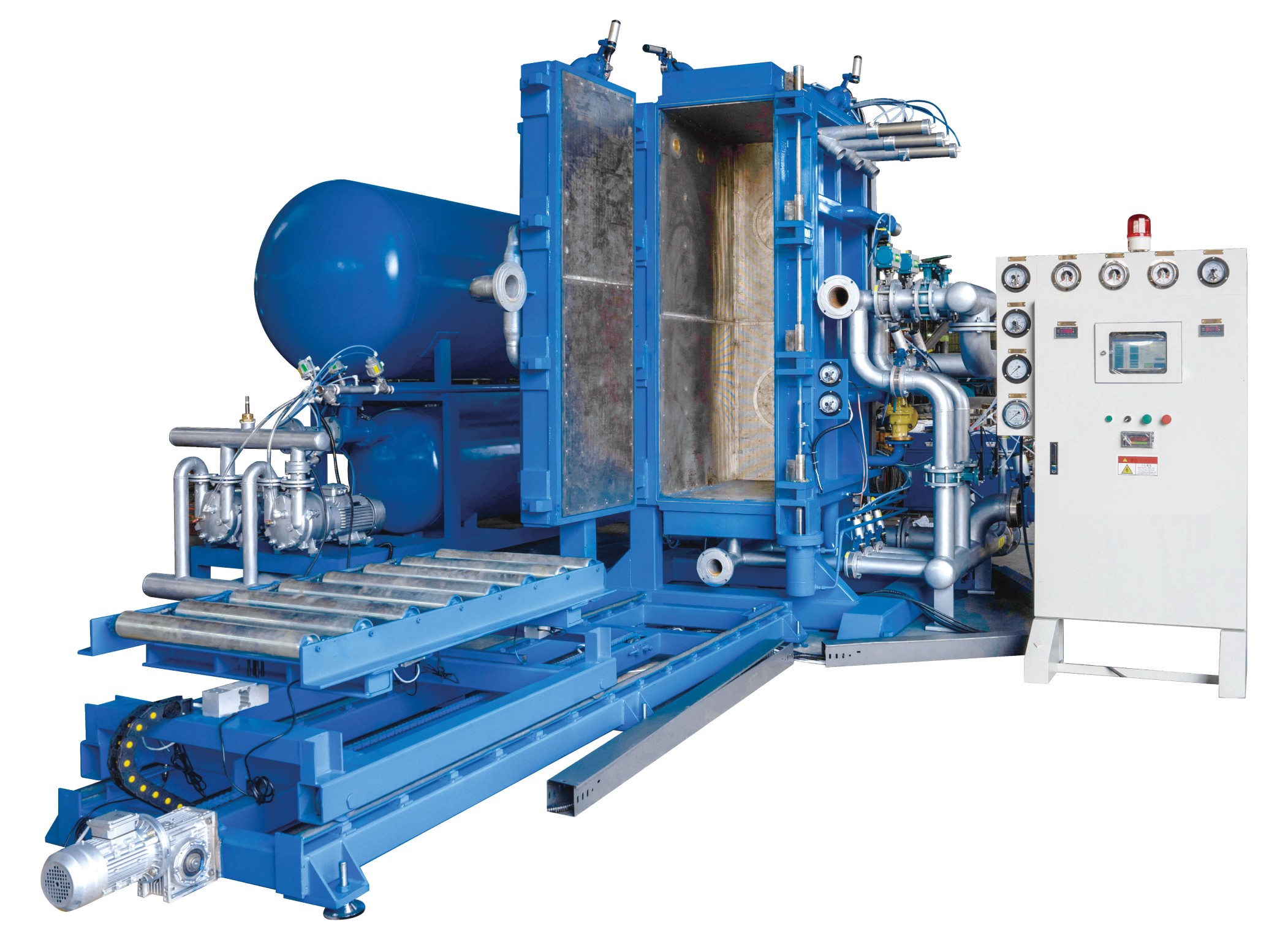

4M Auto EPS Vacuum Block Molding Machine

Technical Specifications of the SPBL4000 EPS Vacuum Forming Machine

The SPBL4000 is a 4-meter vertical fully automatic EPS vacuum forming machine crafted for large-sized EPS foam board production. With its advanced vacuum control system, it promises efficient and stable foam block forming. Designed for industrial-scale operations, this machine minimizes manual intervention, ensuring robust output and precise processing accuracy.

Cavity and Plate Specifications

- Cavity Specifications: 4080 × 1230 × 1030 mm

- Plate Specifications: 4000 × 1200 × 1000 mm

Machine Inlets and Consumption Details

- Steam:

- Entrance: 8 (DN150)

- Consumption: 75-95 Kg/cycle

- Pressure: 0.7-0.9 Mpa

- Compressed Air:

- Entrance: 3 (DN80)

- Consumption: 1.5-2.5 M3/cycle

- Pressure: 0.5-0.8 Mpa

- Vacuum Cooling Water:

- Entrance: 2 (DN50)

- Consumption: 0.8-1.2 M3/cycle

- Pressure: 0.2-0.4 Mpa

Outlet and Drainage

- Sewage Outlet: 8 (DN200)

- Air Outlet: 8 (DN200)

- Vacuum Drain Port: 5 (DN125)

Power and Capacity

- Hydraulic Motor: 7.5 Kw

- High Pressure Blower: 7.5 Kw

- Feeding Fan: 4 Kw

- Vacuum Pump: 22 Kw (11Kw × 2)

- Production Capacity: 15 Kg/m3, 5 min/cycle (May 8th)

Dimensions and Weight

- Dimensions (L × W × H): 8900 × 7250 × 5800 mm (with direct-export conveyor)

- Machine Weight: approximately 14000 Kg

With its vertical structure, the SPBL4000 saves space, fits seamlessly into diverse factory settings, and guarantees superior quality and size consistency. This machine is the optimal choice for EPS processing companies aiming to enhance efficiency and elevate production standards.