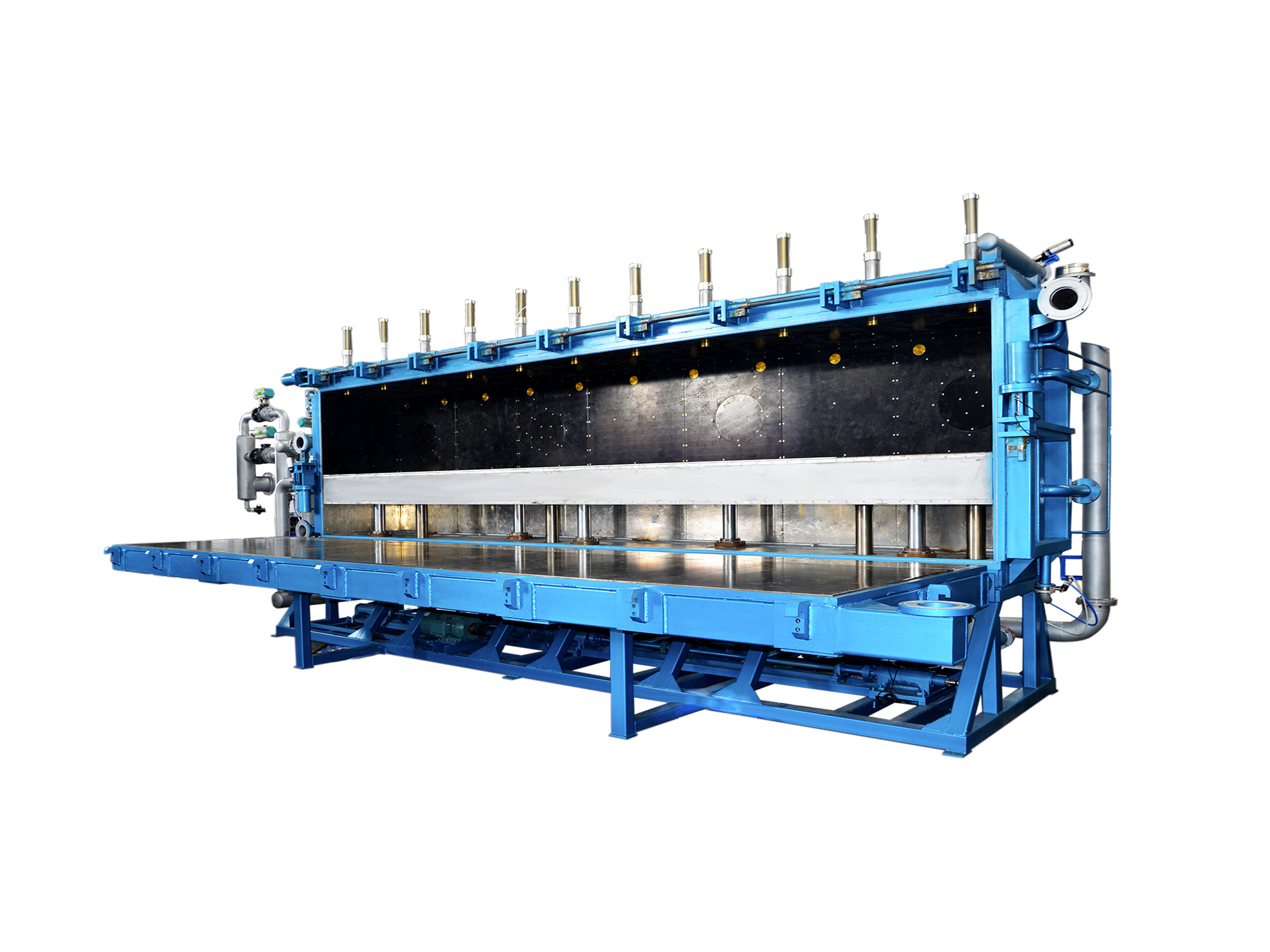

Adjustable EPS Block Molding Machine - Auto Length & Width

Efficient and Versatile Auto Block Moulding Machine with Advanced Control Systems

Introducing our cutting-edge Auto Block Moulding Machine, designed with an Elevating Device Control System, PLC, and human-touch Control. This state-of-the-art machine offers automatic operation, convenient maintenance, and an automatic feeding system for streamlined production processes.

Key Features

- Advanced EPS Penetration: Leveraging a sophisticated EPS penetration heating molding process and optimized pipeline layout for enhanced thermal penetration and foam particle adhesion.

- Automatic and Efficient: Automatic pneumatic and vacuum assistant feeding devices ensure once forming and circular production with minimal downtime.

- High Production Efficiency: Each board takes only 4-8 minutes to produce, ensuring fast cooling speeds and reduced costs.

- Energy-Saving Design: Engineered to optimize energy consumption while maintaining superior molding quality.

- Adjustable Length and Width: Automatic length-width adjustment system supports multi-specification production to adapt to diverse order requirements, minimizing the need for additional cutting processes.

Technical Specifications

- Available in multiple models: SPB2000V, SPB3000V, SPB4000V, SPB6000V, and SPB8000V

- Steam and Compressed Air Entry sizes vary based on model requirements

- Production capacity ranges from 4 to 8 cycles per minute at 15kg/m³

- Automatic control system ensures easy operation and reduced labor costs

Applications

This versatile machine is ideal for producing a variety of EPS products, including:

- Building insulation boards

- Decorative materials

- Packaging foam blocks

Engineered for energy conservation, environmental protection, and large-scale production, this EPS automatic block forming machine is your ultimate choice for enhancing productivity and efficiency in foam board manufacturing.