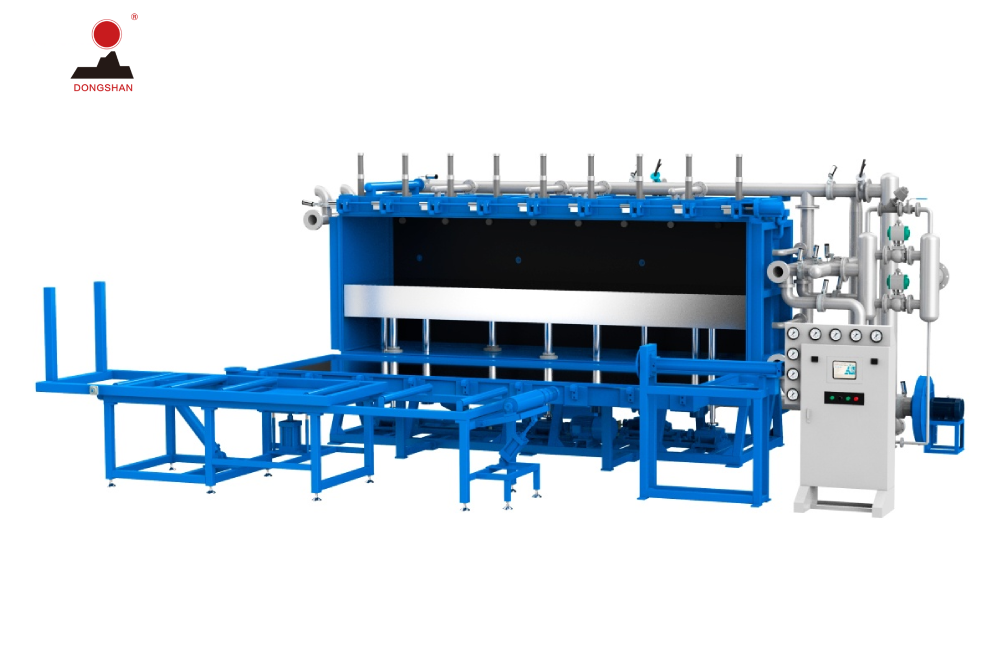

Adjustable EPS Block Molding Machine for Height Control

Advanced EPS Block Forming Machines for Quality Foam Production

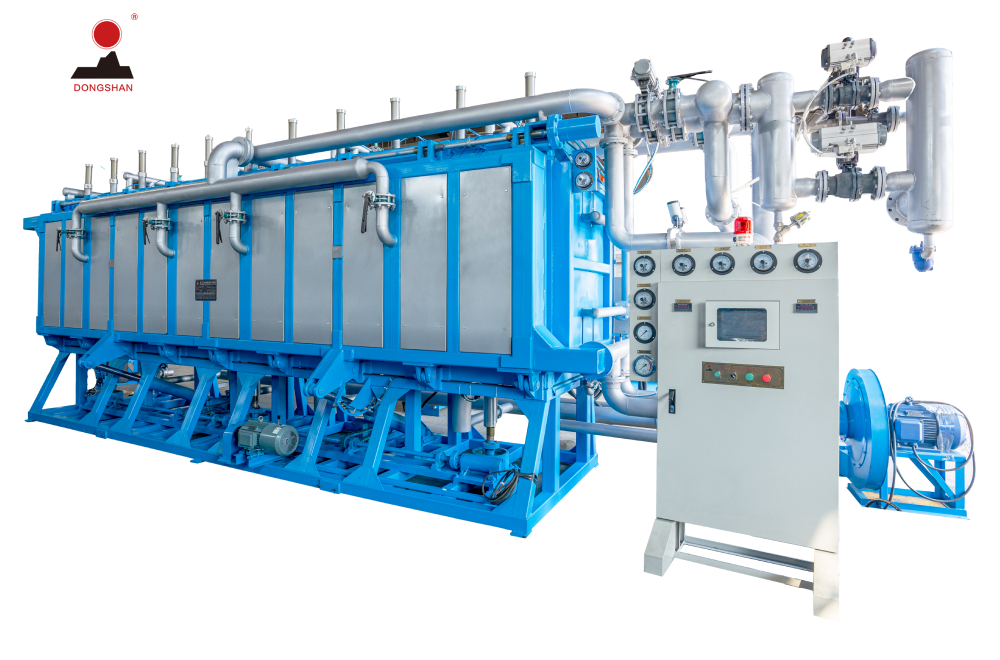

Our cutting-edge EPS block forming machines are designed to meet diverse industrial needs by producing foam blocks in various sizes. With robust construction and smart automation, these machines ensure flexibility and precision in foam block manufacturing.

Versatile Mould Cavity Sizes

- SPB2000V: 2080×(1240-800)×630 mm

- SPB3000V: 3080×(1240-800)×630 mm

- SPB4000V: 4100×(1240-800)×630 mm

- SPB6000V: 6120×(1240-800)×630 mm

- SPB8000V: 8140×1240×630 mm

Innovative Features for Optimal Production

Our EPS machines boast advanced features such as:

- Height Adjustability: Easily adjust the height to produce foam blocks suited for various applications, including insulation and packaging.

- Automated Control System: Streamlines operations, maximizing efficiency and minimizing manual intervention.

- Energy-Saving Steam Heating: Contributes to cost-efficiency while ensuring uniform block density.

- Efficient Cooling System: Ensures stable and durable foam structure.

Technical Specifications

Our machines are engineered to deliver unmatched performance:

- Steam Entry: Varied sizing from 5 (DN125) to 8 (DN200) to adapt to your needs.

- Compressed Air System: Entry sizes ranging from 1.5 (DN40) to 3 (DN80).

- Water Consumption: Minimal usage with specifications from 0.4 to 2 m³/cycle.

- Capacity: Up to 8 cycles/min for high-volume production.

Dimensions and Load Capacity

Our machines offer size and power options to suit any production scale:

- Overall Dimensions: From 5700×4000×3300 mm to 15700×4600×3500 mm.

- Weight: Ranges from 8,000 KG to 21,000 KG, ensuring stability and robust performance.

- Power: Connected load options from 20/35 KW to 31/55 KW for customized energy needs.

Applications

Our EPS block forming machines are ideal for producing a wide range of products:

- Building insulation boards

- Packaging boards

- Industrial foam products

These machines stand out for their durable build and ease of operation, making them perfect for long-term, continuous production.