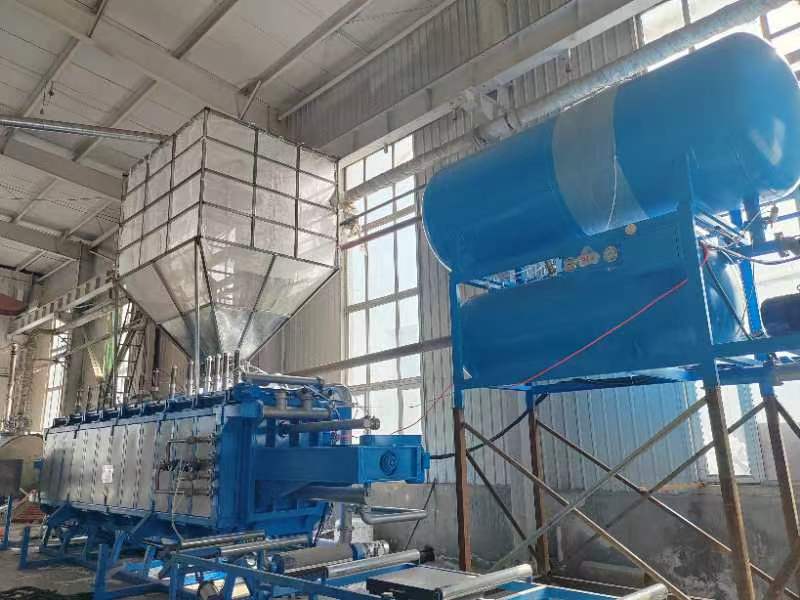

Adjustable Length EPS Foam Block Molding Machine

Advantages of Plate Machine Equipment

The plate machine equipment offers superior performance and operational benefits that are crucial across various industries. This equipment description is structured around four key perspectives: safety, quality, efficiency, and energy savings.

Equipment Performance Specifications

- Mould Cavity Size (mm):

- SPB2000LZ: 2040×1240×1030

- SPB3000LZ: 3060×1240×1030

- SPB4000LZ: 4080×1240×1030

- SPB6000LZ: 6080×1240×1030

- Block Size (12g/L) (mm):

- SPB2000LZ: 2000×1200×1000

- SPB3000LZ: 3000×1200×1000

- SPB4000LZ: 4000×1200×1000

- SPB6000LZ: 6000×1200×1000

Production Efficiency

Our equipment is designed for optimal performance with minimal wastage. The adjustable length feature allows flexible production of EPS foam blocks, enhancing efficiency and reducing raw material waste.

Energy-Saving Technology

The advanced heating and steam control systems integrated into the equipment ensure energy savings while maintaining high production standards. The energy consumption metrics per cycle are as follows:

- Steam Consumption (Kg/Cycle):

- SPB2000LZ: 70–100

- SPB3000LZ: 100–130

- SPB4000LZ: 130–160

- SPB6000LZ: 150–180

Precision and Quality

Our plate machine equipment guarantees high forming accuracy through automated control, ensuring stable and precise product sizes. This precision is pivotal for various applications, including construction insulation, packaging, and decorative products.

Versatile Applications

The equipment's versatility allows it to cater to diverse production requirements, making it suitable for manufacturing building insulation boards, packaging cushioning materials, and various decorative items.