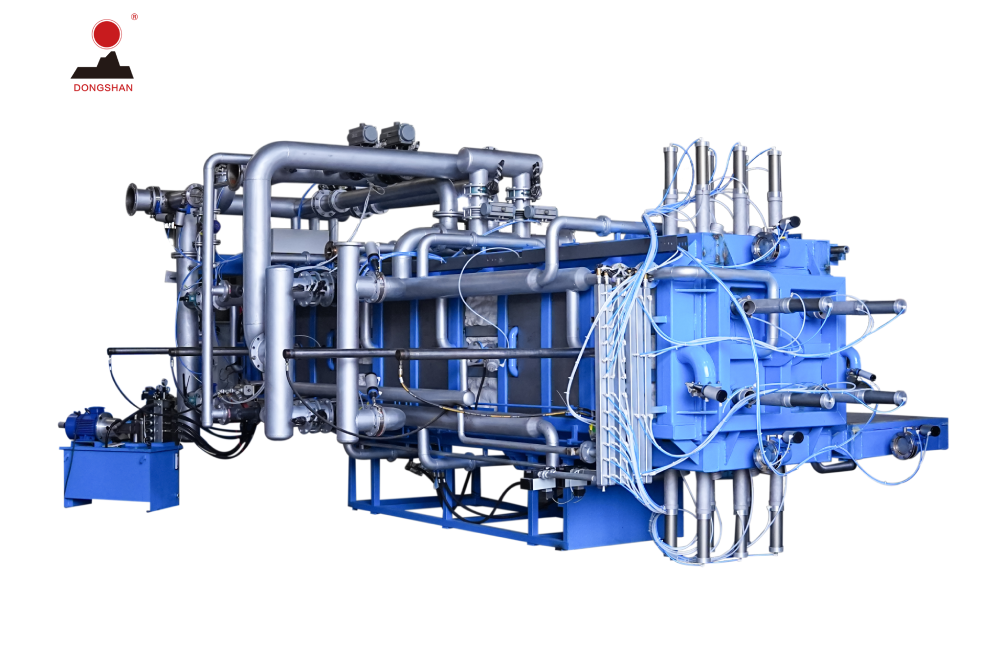

Advanced European EPS Block Molding Machine

High-Performance EPS Automatic Shape Moulding Machines

Hangzhou Fuyang Dongshan Plastic Machinery Co., Ltd., with nearly 20 years of experience, specializes in manufacturing top-quality EPS and EPP foam plastics machines. Our commitment to quality and innovation integrates independent research and development, superior manufacturing techniques, comprehensive sales, and dedicated service.

Robust Machine Structure for Enhanced Durability

- The inner molds are crafted with strong rectangular tubes and steel plates, treated with electric furnace stress relieving annealing for a high-strength frame.

- All block mould frames undergo heat treatment to release welding pressure and prevent deformation.

- Post heat-treatment, sand blasting is employed to enhance rust prevention, improving anticorrosion performance.

- Our EPS styrofoam block moulding machines promise long-term reliability and performance.

Efficient Steam System

- Three ball valves replace one big valve, saving 20% of steam and enhancing machine stability.

- ISO-standard butterfly valves further improve durability and block moulding efficiency.

- 3D heating penetration shortens heating time and increases energy savings.

- The stainless steel platen surface supports heavy density block production while extending machine lifespan.

Advanced Control System

- Features Mitsubishi PLC and Schneider touch screen for user-friendly operation.

- Equipped with a material level sensor for precise filling control.

- Foam pressure sensor monitors block cooling to ensure optimal mould performance.

- Fully automated process for seamless operation.

Vertical Frame Type Design

- Space-efficient design with improved drainage performance.

- Reduces block moisture content for better product quality.

- Remote control system allows real-time monitoring of the entire process.

Specifications

| Item | Unit | SPB2000LZ | SPB3000LZ | SPB4000LZ | SPB6000LZ |

|---|---|---|---|---|---|

| Mould Cavity Size | mm | 2040×1240×1030 | 3060×1240×1030 | 4080×1240×1030 | 6080×1240×1030 |

| Block Size(12g/L) | mm | 2000×1200×1000 | 3000×1200×1000 | 4000×1200×1000 | 6000×1200×1000 |

| Steam Inlet | Inch | 4"(DN100) | 5"(DN125) | 6"(DN150) | 8"(DN150) |

Customer Success Stories

Our valued customers have witnessed significant improvements in production efficiency and product quality using our EPS automatic shape moulding machines. Join the ranks of satisfied clients and experience unparalleled performance in foam plastics manufacturing.