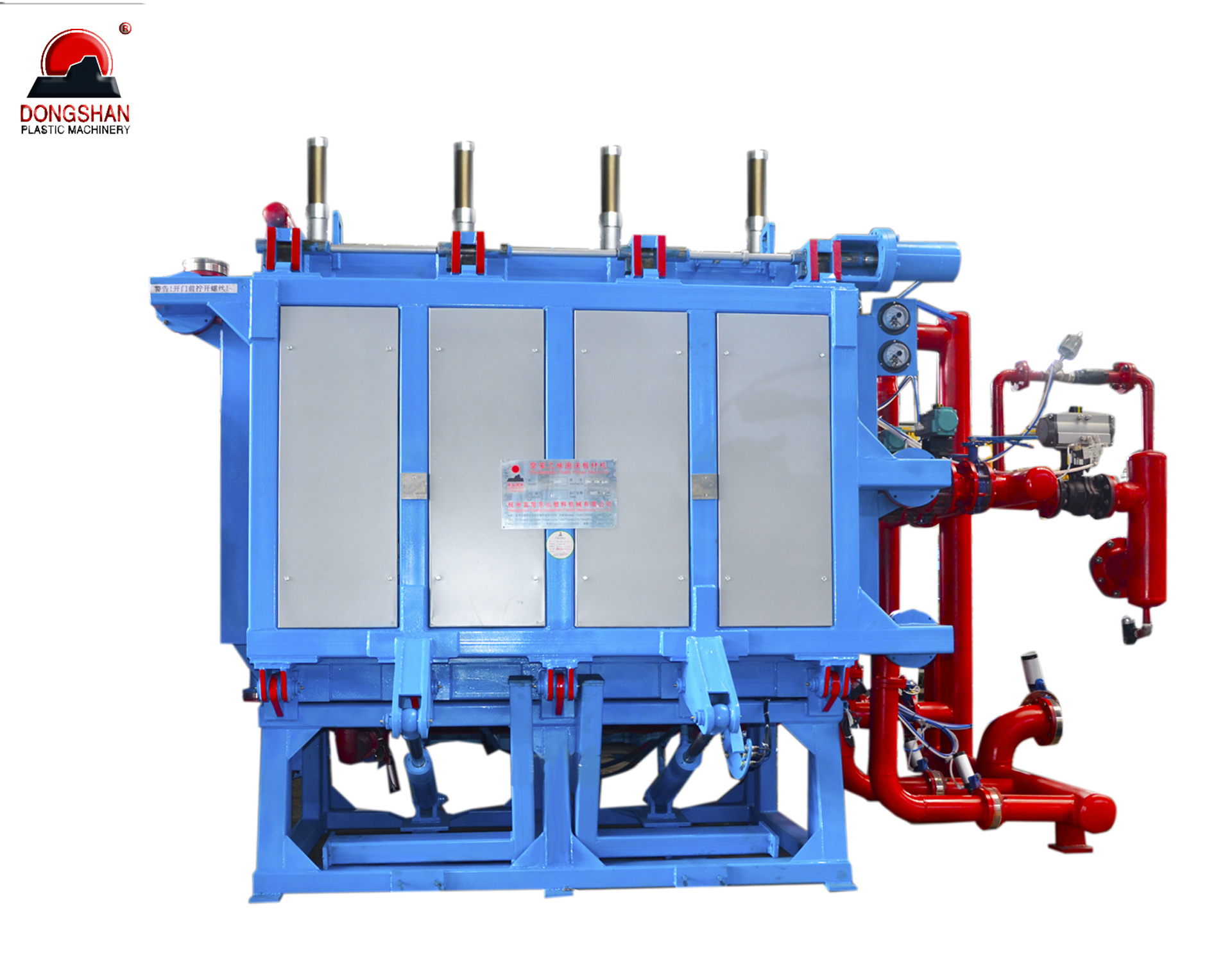

Air-Cooling EPS Block Molding Machine - Automated System

Advanced EPS Block Forming Machines

Revolutionize your production line with our EPS fully automatic air-cooled block forming machines, designed for efficiency and precision. Our state-of-the-art equipment replaces traditional water cooling methods, reducing energy consumption and operational costs while ensuring the highest quality EPS foam products.

Core Features of Our EPS Block Forming Machines

- Air-Cooling Technology: Minimize water usage and lower your operating expenses with our innovative air-cooling system.

- Fully Automatic Control: Simplify operations and reduce labor demands with our automated system that enhances productivity.

- High-Efficiency Production: Achieve rapid prototyping and sustain large-scale production with our highly efficient machinery.

- Wide Application: Ideal for manufacturing EPS products like insulation boards, packaging materials, and architectural decorations.

Technical Specifications

Explore the detailed specifications of our available models to find the perfect match for your production needs.

- Mould Cavity Size (mm): Ranging from 2040*1020*580 to 8100*1240*630

- Block Size (mm): From 2000*1000*560 to 8000*1200*600

- Steam Entry: Sizes from 2.5 to 6 for varied consumption needs

- Compressed Air Entry: Available from 1.5 to 3 to accommodate different pressure requirements

- Drainage Steam Vent: Options from 4 to 8 to support efficient steam release

- Connected Load/Power (Kw): Varies between 7 and 9.5, allowing flexibility for your energy needs

- Overall Dimensions (L*W*H mm): Spanning from 3800*2000*2100 to 11500*2600*3300 to fit your spatial constraints

- Weight (kg): Models range from 3500 to 12000 kg for various production scales

Optimize Your Production with Next-Gen EPS Machinery

Ensure precise block dimensions and uniform density with our cutting-edge machines. Designed to integrate seamlessly into your production line, they are the ideal solution for efficient and sustainable EPS manufacturing. Choose our technology to stay ahead in the competitive market of EPS products.