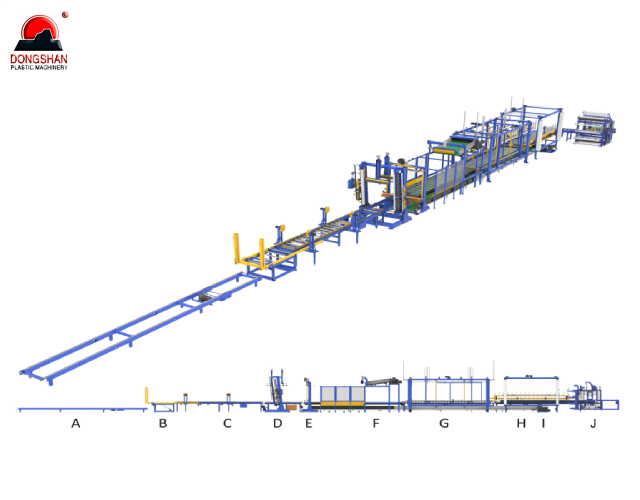

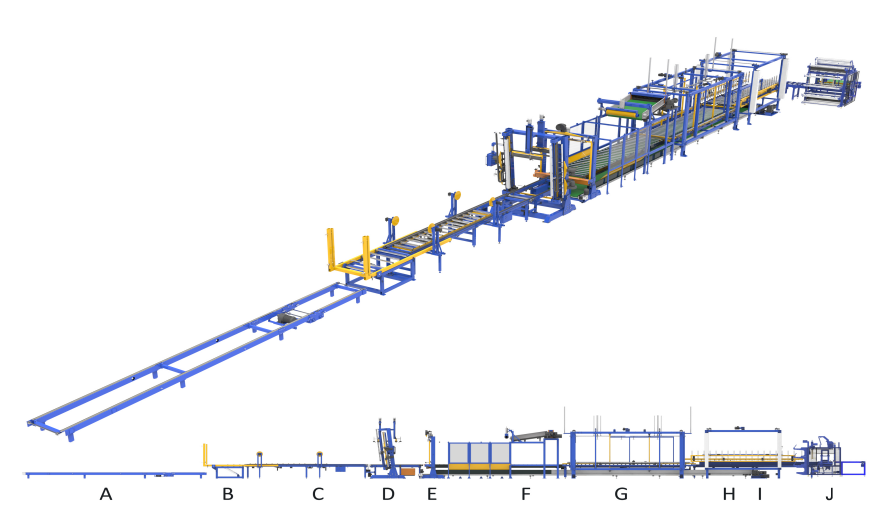

Automated EPS Block Cutting Line

Advanced Device Parameters for Precision Cutting

Our cutting-edge device is designed to handle a variety of project needs with precision. The device offers the following parameters:

- Suitable Product Size: 4000*1300*600 mm

- Minimum Cutting Thickness: 15 mm

- Cutting Speed: 0.6-2 meters per minute

- Horizontal Hanging Wires: 50 pieces

- Vertical Hanging Wires: 5 pieces

- End Face Direction Hanging Wires: 12 pieces

- Cutting Wire Specifications: 0.35-0.6 mm

- Power: 26 Kw

- Voltage: 380V/50HZ

- Total Weight: 5800 Kg

- Dimensions: 30000*2400*2500 mm

Streamlined Cutting Process for Maximum Efficiency

Our device automates various steps in the cutting process to improve efficiency and accuracy:

Plate Storage Line

Capable of storing six plates, the line can be manually loaded via forklift or connected automatically to a conveyor in the drying room. Configurable to suit plant layout, either straight or at a 90-degree angle.

Hydraulic Turning Frame

Driven by hydraulic pressure for stability, this frame safely lays plates for cross-cutting once they're aligned flat.

Cross-Cutting Alignment System

Ensures precise alignment and rapid transition to the next stage, increasing cutting efficiency.

High-Precision Cross-Cutting Frame

Equipped with an automatic wire adjustment system, adjustable pressure rollers, and a vibration cutting system to enhance accuracy and speed.

Vertical Cutting Frame

Features a vibration cutting system, cooling via fans, and optional automatic adjustments and wire breakage detection.

Upper Plate Skin Pre-Crushing

Utilizes suction and a conveyor system to prepare plates for pre-crushing, optimizing the next processing step.

Automatic Plate Alignment and Cutting System

Ensures accurate cuts with built-in systems for precision and optional enhancements for efficiency.

Stacking and Packaging Mechanism

Facilitates seamless transitioning to packaging, ensuring both upper and lower halves of plates are expertly wrapped.

Bottom Waste Pre-Crushing

Efficiently handles scrap, preparing it for further processing and increasing overall operational efficiency.

EPS Sheet Film Wrapping Machine

Connects to the stacking mechanism for secure, tight packaging capable of enduring long-distance transport without heat shrinkage.

Key Features of Our Cutting Machine

- Automatic Wire Adjustment: 1-3 minutes for quick and precise adjustments.

- Vibration Cutting: Speeds up to 2 meters per minute for high efficiency.

- Continous Work Mode: Processes up to 5 plates simultaneously.

- Computer-Controlled Speed: Enhances production by reducing loading and adjusting time.

- Custom Cutting: Directly meets customer size requirements.

- Full Computer Automation: Ensures comprehensive monitoring and efficiency.