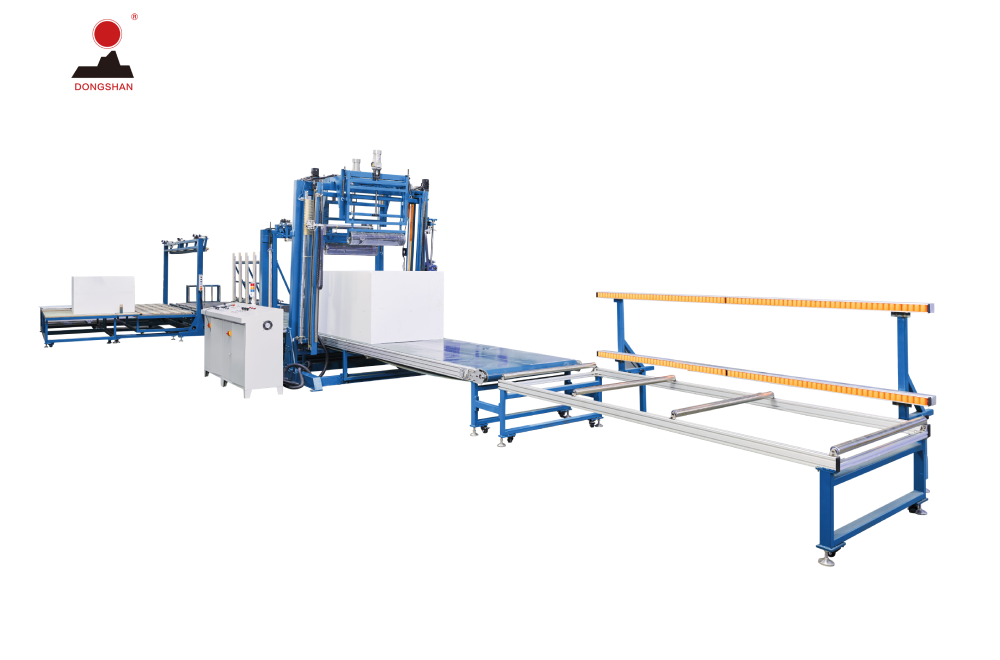

Automated EPS Cutting Line for Industrial Use

Core Advantages of the Industrial-Grade Cutting System

- High-Precision Processing

- Utilizes linear guides with repeatability of ±0.1mm

- Imported German servo drive system

- Adjustable cutting speed: 2-20m/min

- Supports 3D cutting and bevel processing with angle adjustment ±45°

- Smart Production System

- CCD vision positioning system for automatic material edge recognition

- Fully automatic PLC control with a 10.1-inch industrial touchscreen

- Optional robotic automatic stacking unit for unmanned production

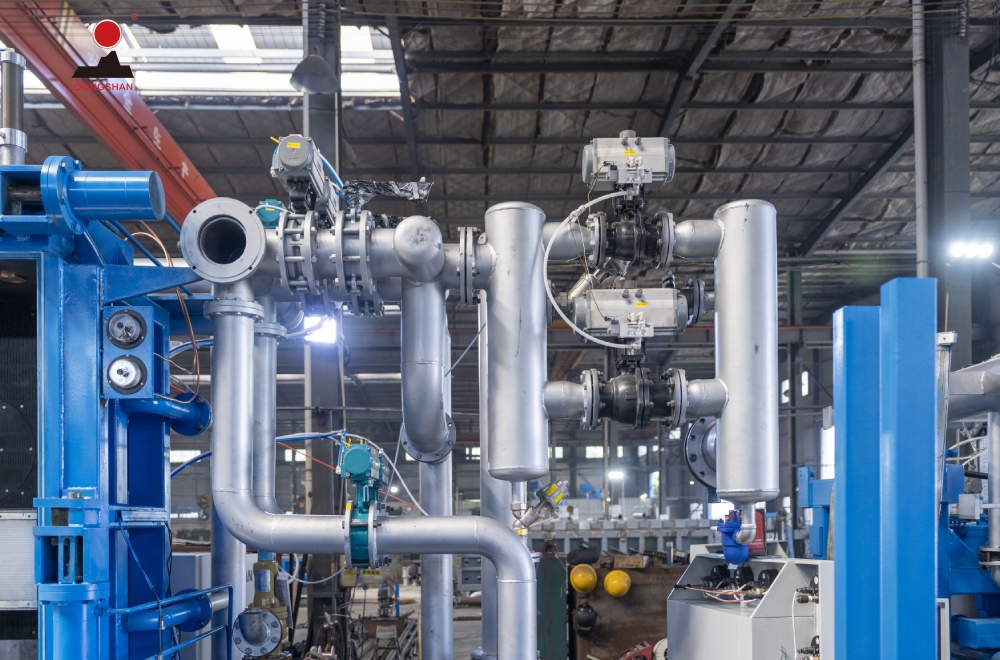

- Long-lasting and Stable Operation

- Heavy-duty steel structure with 2000kg load capacity

- Automatic lubrication system prolonging lifespan of key components by 50%

- Designed for 24-hour continuous operation with a failure rate of less than 0.5%

Basic Technical Specifications

- Suitable Block Size: 4000*1300*1300 mm

- Minimum Cutting Thickness: 10 mm

- Cutting Speed: 0.5-1.5 m/min

- Max. Wires in Horizontal Piece: 50

- Max. Wires in Vertical Cutting Piece: 15

- Max. Wires in Cross Cutting Piece: 15

- Hot Wire Specification: 0.4-0.8 mm

- Connected Load: 24.8 kW

- Weight: 3500 kg

- Contour Size: 18000*3000*2420 mm

Operational Efficiency and Capacity

This cutting system is designed for high-efficiency EPS sheet and block processing, making it suitable for large-scale industrial production.

- Fully automatic continuous cutting that minimizes the need for manual operations.

- Precision cutting with advanced guidance system and control technology for uniform sizes and neat edges.

- High-capacity processing supporting mass production for industrial-grade EPS manufacturing.

- Energy-saving design to optimize energy consumption, improve production efficiency, and reduce costs.

Model: SPC 4000 (Three Table)

- Belt conveyor for efficient movement of materials.

- Production Capacity: 7-10 blocks per hour for 4-meter blocks.