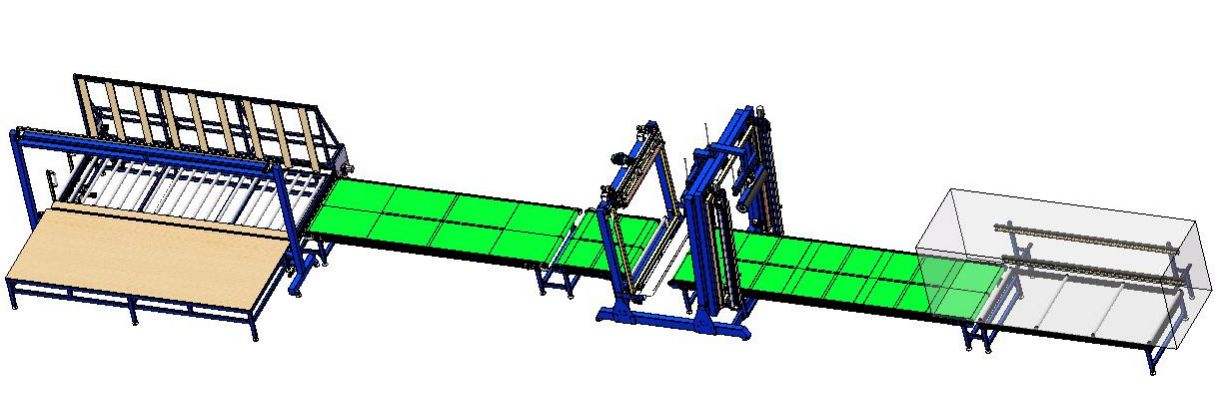

Automatic EPS Cutter SPC4000 – 3-Table Continuous Design

Advanced SPC4000 EPS Cutting Machine

The SPC4000 EPS cutting machine with three consecutive benches is engineered for top-tier performance in EPS sheet production. This automated device is suited for the manufacture of insulation boards, packaging boards, and EPS boards for construction.

Key Features

- Individual Voltage Adjustment: Horizontal, vertical, and cross-cutting voltages can be adjusted individually using separate transformers and multi-stage switches.

- Flexible Movement Control: Horizontal, vertical, and cross-cutting movements are adjustable with frequency converters.

- Automatic Process Control: From block alignment to horizontal cutting, all processes are controlled automatically, ensuring precision and efficiency.

- Easy Operation:

- Horizontal cutting wires are set automatically.

- Cross and vertical cutting wires can be quickly set with rulers on both sides, reducing setup time significantly.

- Block alignment ensures accurate positioning, enhancing cutting accuracy.

- Enhanced Cutting Capacity: Vibration cutting increases cutting capacity by 30% for both horizontal and vertical cuts.

- Efficient Cooling: Equipped with a strong fan for wire cooling on all cutting sides.

- Safety First: Features multiple pause buttons and an emergency stop button for immediate shutdown in emergencies.

Technical Specifications

- Suitable Block Size: 4000mm x 1300mm x 1300mm

- Minimum Cutting Thickness: 10mm

- Cutting Speed: 0.5-1.5 m/min

- Maximum Horizontal Wires: 50

- Maximum Vertical Wires: 15

- Maximum Cross Wires: 15

- Hot Wire Specification: 0.4-0.8 mm

- Connected Load: 24.8 kW

- Weight: 3500 kg

- Contour Size: 18000mm x 3000mm x 2420mm

- Conveyor: Belt conveyor for movement

- Production Capacity: 7-10 blocks per hour for 4-meter blocks

Why Choose the SPC4000 EPS Cutter?

With its precision guide rails and CNC system, the SPC4000 guarantees accurate cutting sizes and neat edges. Built for reliability and mass production, it promises energy-saving advantages and high efficiency, making it the optimal choice for high-volume EPS sheet production.