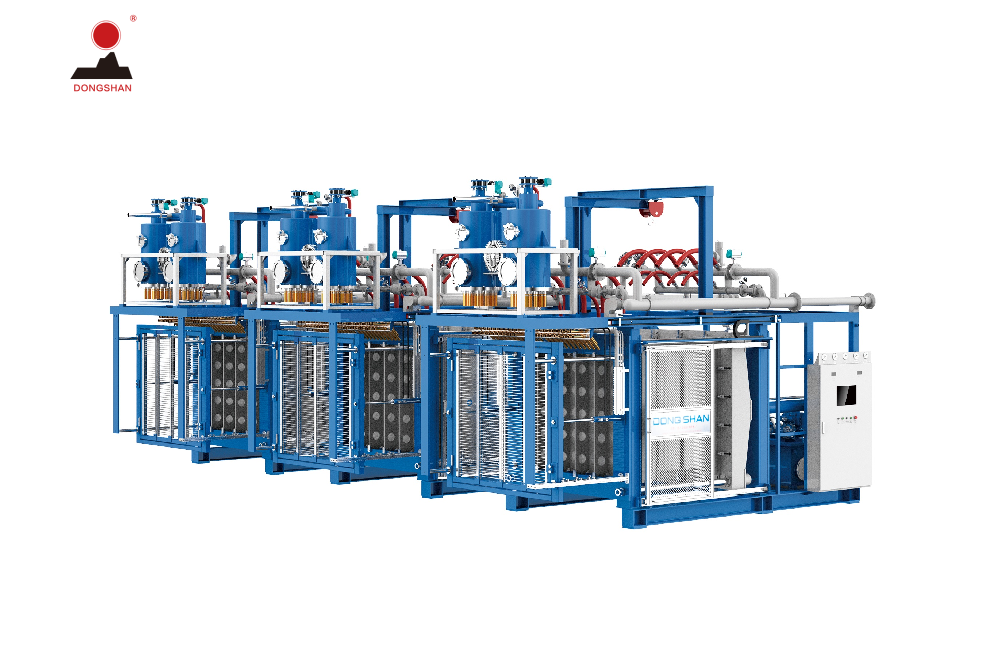

Automatic EPS Shape Molding Machine for Packaging & Insulation

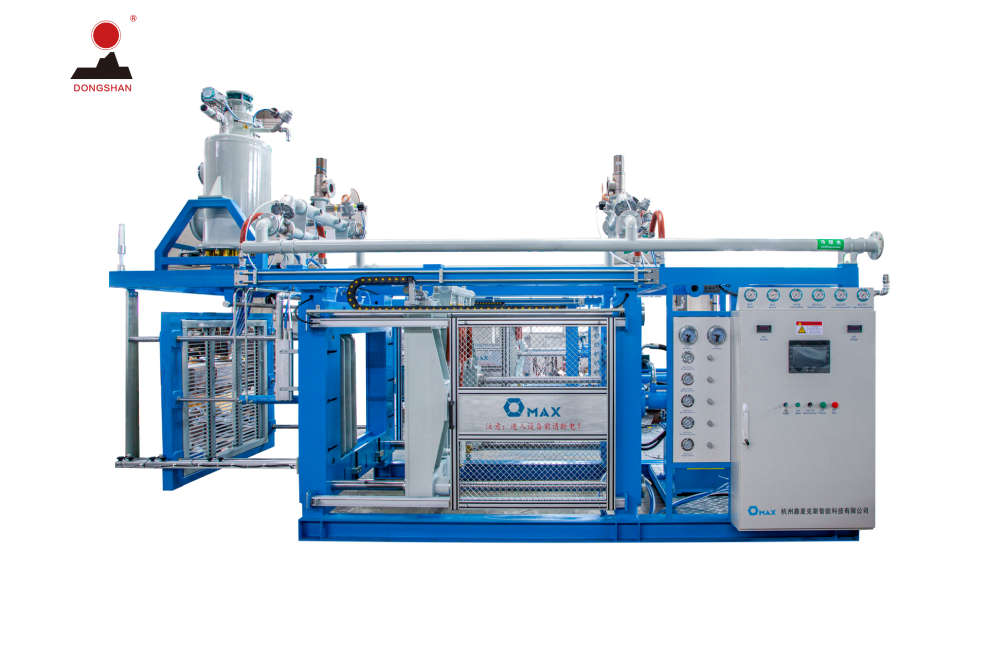

EPS Fully Automatic X-A Type Shape Molding Machine

This state-of-the-art EPS Fully Automatic X-A Type Shape Molding Machine is designed to deliver precision and efficiency in EPS molding production. Thanks to its advanced automated control system, the machine supports a variety of mold specifications, making it ideal for crafting high-quality building insulation materials and customized EPS products.

Key Features

- Fully Automatic Operation: Minimizes the need for manual intervention, significantly boosting production efficiency.

- High-Precision Forming: Ensures consistency in product size and a superior quality finish.

- Energy-Saving and Eco-Friendly Design: Streamlines steam and energy consumption to lower production costs.

- Versatile Applications: Perfect for the packaging industry, thermal insulation materials, and industrial EPS parts.

Application Technical Data

- Mold Outer Diameter (OD): Available in varied sizes ranging from 1200×1000 mm to 2200×1600 mm.

- Effective Forming Area: Varies from 1000×800 mm to 1950×1350 mm.

- Maximum Product Height: Up to 400 mm for all models.

- Steam Pipeline and Pressure: Available up to DN 125 with a working pressure of 3~6 Kg/cm².

- Air Pipeline Interface: DN 65 to DN 80 with a working pressure of 4~5 Kg/cm².

- Hydraulic Oil Pump Motor: Power ranging from 5.5 Kw to 11 Kw, complemented by efficient oil pumps.

- Mold Opening and Closing Cylinder: Extensive cylinder sizes for optimized operations.

- Barrel Capacity: 0.15 to 0.3 m³, ensuring robust material processing.

- Compact Design: Outer size variants from 5250×1750×3785 mm to 5632×2620×4100 mm, adaptable for diverse workspace needs.

Machine Specifications

With a focus on both efficiency and environmental responsibility, this EPS molding machine is engineered to offer high-precision forming and comprehensive automatic operation. The inclusion of energy-saving measures ensures optimized steam and energy usage, aligning with cost-reduction goals. Explore the vast range of specifications tailored to meet the demanding needs of modern EPS applications.