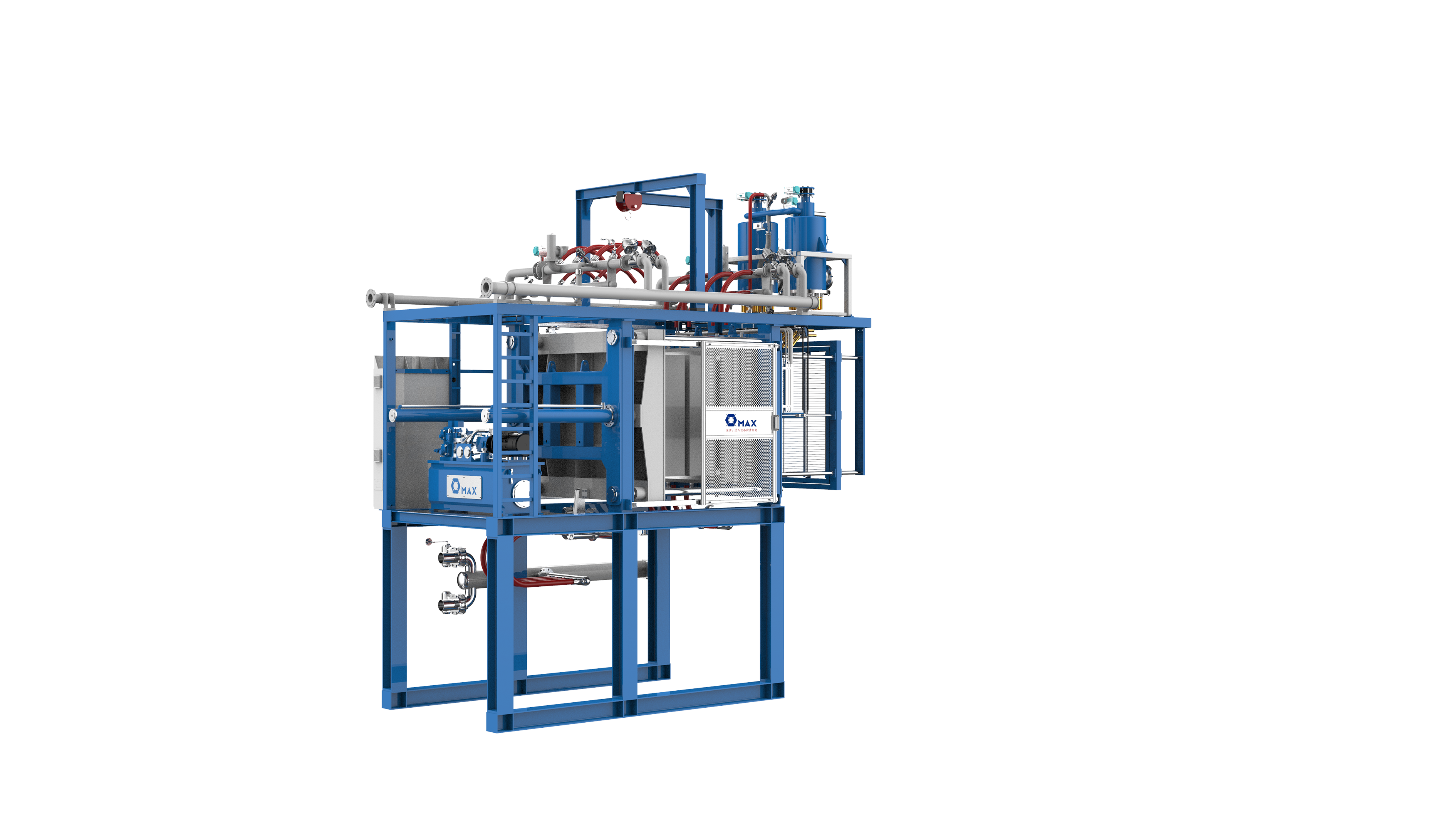

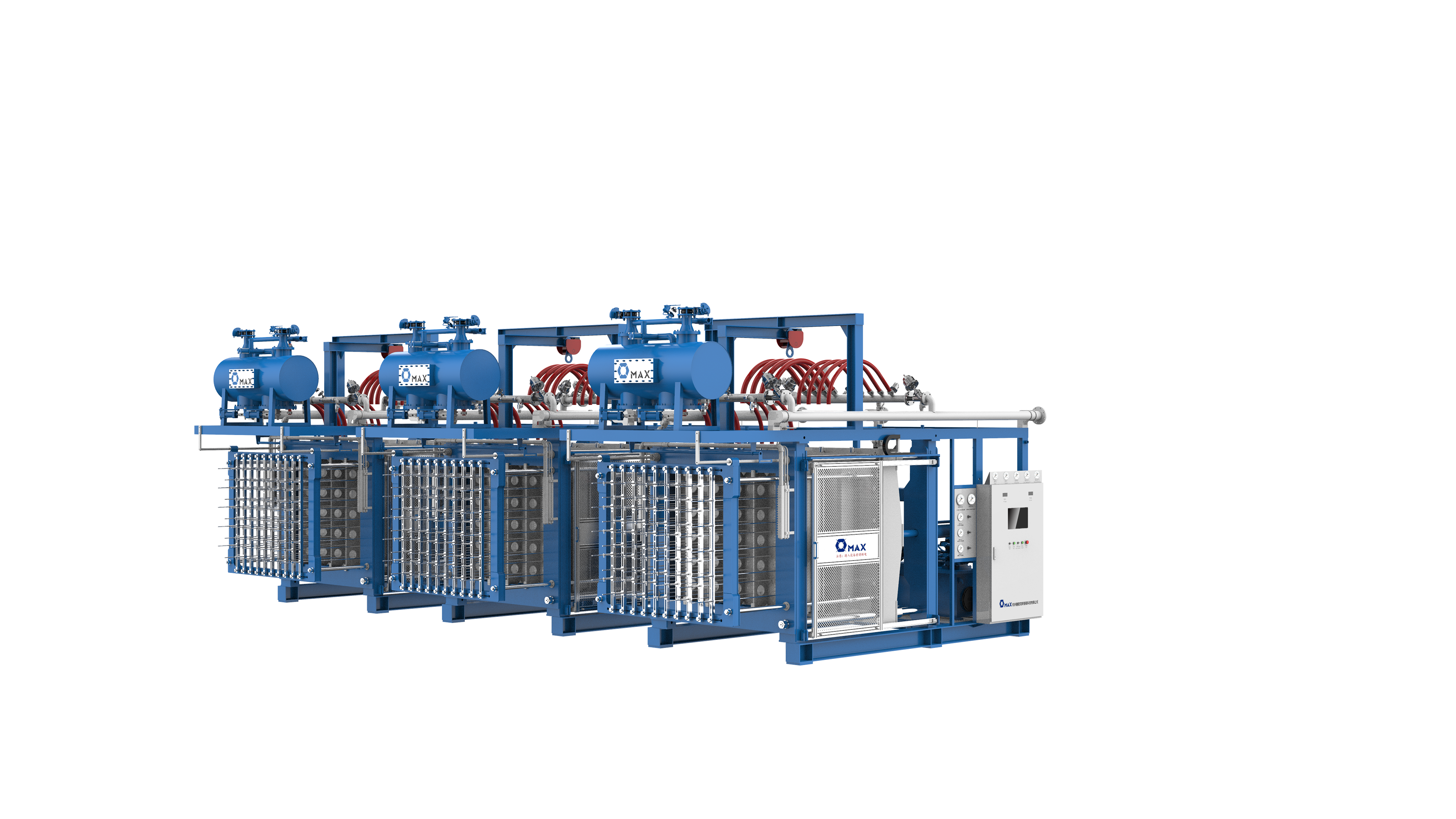

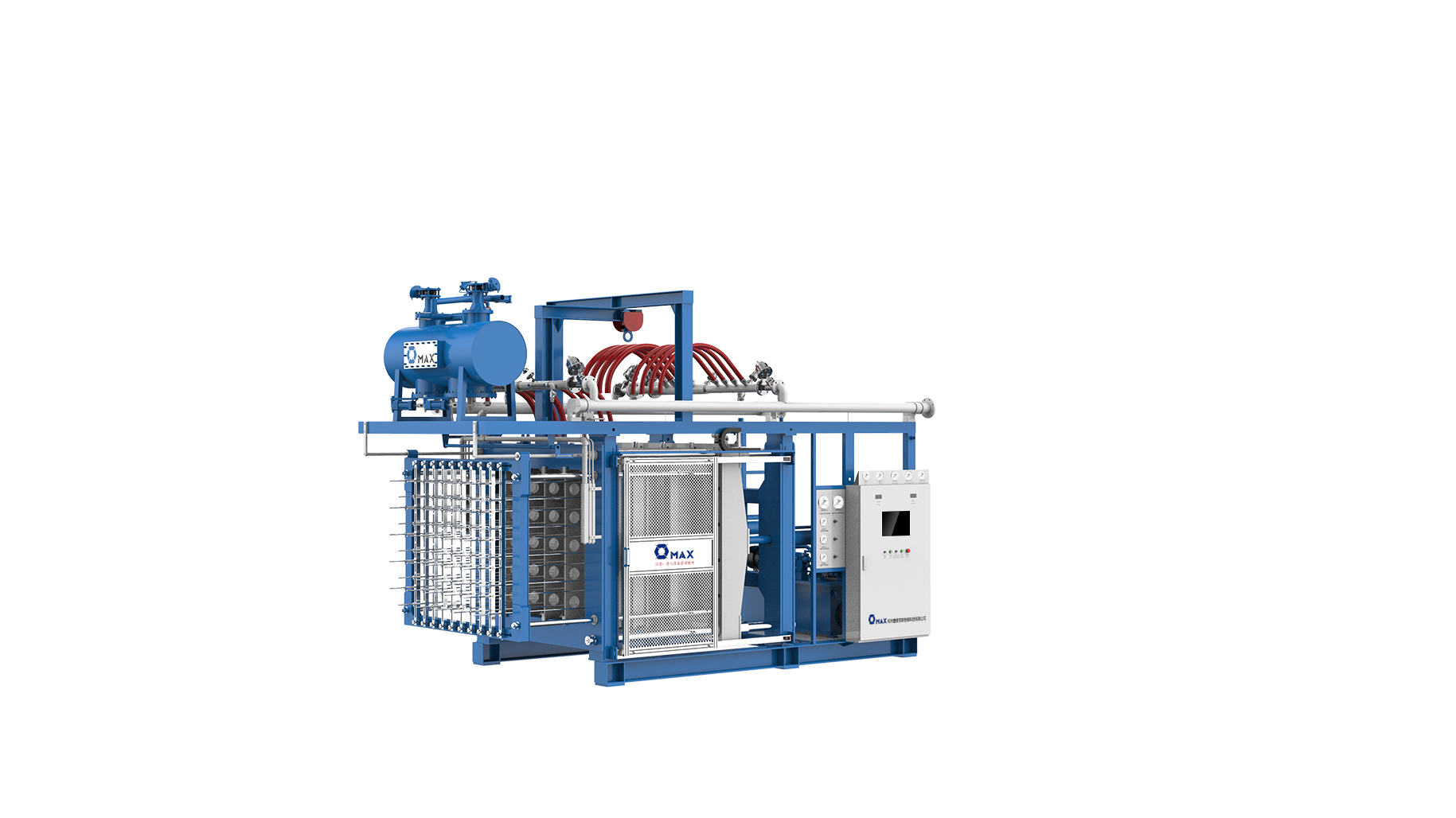

Energy-Efficient EPS Molding Machine - High Performance

Advanced EPS Molding Machines for Optimal Efficiency

Enhance your production capabilities with our high-efficiency and energy-saving EPS molding machines. Designed with the latest in heating and steam control technology, these machines ensure superior product molding quality while significantly reducing energy consumption.

Specifications and Features

- Mold Sizes: Ranging from 1400x1200mm to 2000x1800mm, accommodating various production needs.

- Max Product Size: Supports products up to 1800x1600mm with a consistent max height of 400mm.

- Efficiency: Equipped with a hydraulic oil pump motor ranging from 5.5 Kw to 7.5 Kw, optimizing energy usage.

- Connectivity: Standardized pipe connectors for steam, air, and cooling water, ensuring seamless integration and operation.

Intelligent Operating System

Our EPS machines are equipped with an intelligent operating system that minimizes manual operations and enhances production stability. The high degree of automation makes it suitable for continuous production demands.

Cost-Effective and Environmentally Friendly

The innovative design not only shortens the production cycle but also aids in energy conservation and cost reduction. Ideal for producing a variety of EPS products, including packaging, insulation, and industrial materials, these machines support long-term production needs with minimal environmental impact.

Technical Details

- Clamping Force: Max of 38 T to accommodate various molding requirements.

- Material Handling: Featuring material outlets ranging from 24 to 44 pieces for efficient throughput.

- Dimensions and Weight: Models available with dimensions from 5300x2400x3700 to 5300x2800x3970 and weights from 6.5 T to 9.0 T.

Invest in our EPS molding machines for a reliable, efficient, and sustainable production solution.