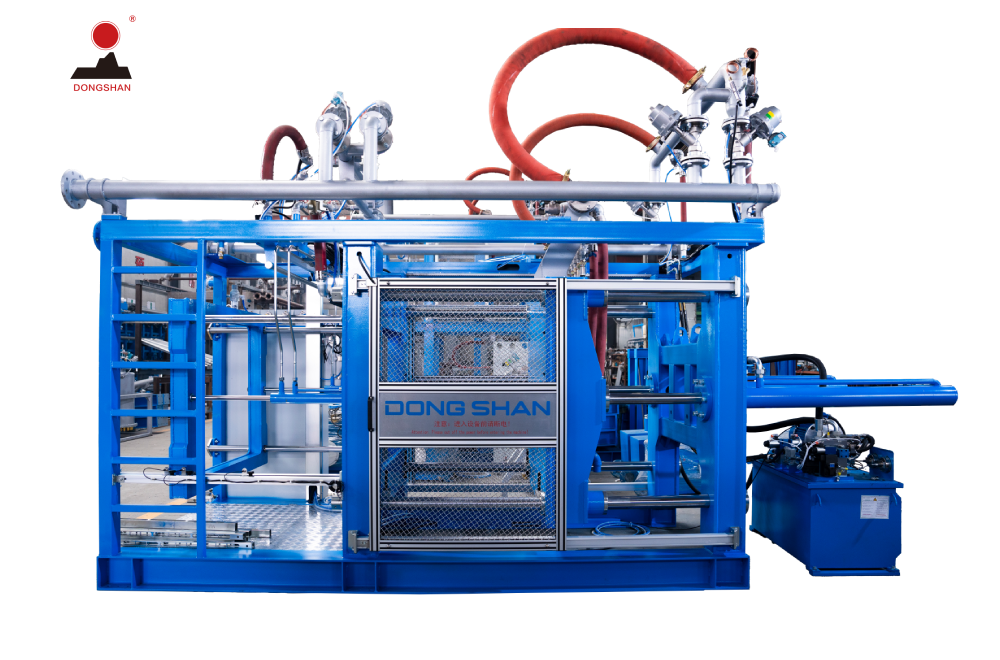

EPP Auto Shape Molding Machine for Efficient Production

Technical Specifications of EPP Foam Plastics Machines

Hangzhou Fuyang Dongshan Plastic Machinery Co., Ltd. has excelled in the manufacturing of EPS and EPP foam plastics machinery for nearly two decades. Renowned for integrating independent research and development with manufacturing prowess, our machines are a testament to quality, durability, and superior engineering.

Mold Frame Dimensions

- EPP813: 1430X930 mm

- EPP1214: 1530X1330 mm

- EPP1318: 1930X1430 mm

Rear Window Size

- EPP813: 1350X850 mm

- EPP1214: 1450X1250 mm

- EPP1318: 1850X1350 mm

Effective Molding Area

- EPP813: 1200X700 mm

- EPP1214: 1300X1100 mm

- EPP1318: 1700X1200 mm

Maximum Product Height

- Common across all models: 400 mm

Steam System Specifications

- Steam Pipeline: DN 100 (EPP813), DN 125 (EPP1214 & EPP1318)

- Mold Interface: DN 40X6 (EPP813) and DN 40X8 (EPP1214 & EPP1318)

- Working Pressure: Range of 5~8 Kg/cm²

Air System Specifications

- Pipeline Interface: DN 65 (EPP813), DN 80 (EPP1214 & EPP1318)

- Working Pressure: Range of 4~5 Kg/cm²

Cooling Water System

- Pipeline Interface: DN 80 (EPP813), DN 100 (EPP1214 & EPP1318)

- Working Pressure: 3~4 Kg/cm²

- Mold Interface: DN 25X6 (EPP813), DN 25X8 (EPP1214 & EPP1318)

Sewage System

- Vacuum Interface: DN 100 (EPP813), DN 125 (EPP1214 & EPP1318)

- Fixed/Movable Drainage: DN 80 (EPP813), DN 100 (EPP1214 & EPP1318)

- Drain Pipe Interface: DN 125 (EPP813), DN 150 (EPP1214 & EPP1318)

- Mold Interface: DN 40X6 (EPP813), DN 40X8 (EPP1214 & EPP1318)

Hydraulic System Performance

- Oil Pump Motor: 7.5 Kw (EPP813), 11 Kw (EPP1214 & EPP1318)

- Oil Pump Capacity: 23+53 L/min (EPP813), 25+75 L/min (EPP1214 & EPP1318)

- Maximum Clamping Force: 50 T (EPP813), 90 T (EPP1214), 100 T (EPP1318)

- Mold Opening/Closing Cylinder: 125X1360/2 mm (EPP813), 100X1360/2 mm (EPP1214 & EPP1318)

- Clamping Cylinder: Not applicable for EPP813, 125X1360/4 mm (EPP1214 & EPP1318)

- Demolding Cylinder: 50X30X450 mm (EPP813), 70X40X450 mm (EPP1214 & EPP1318)

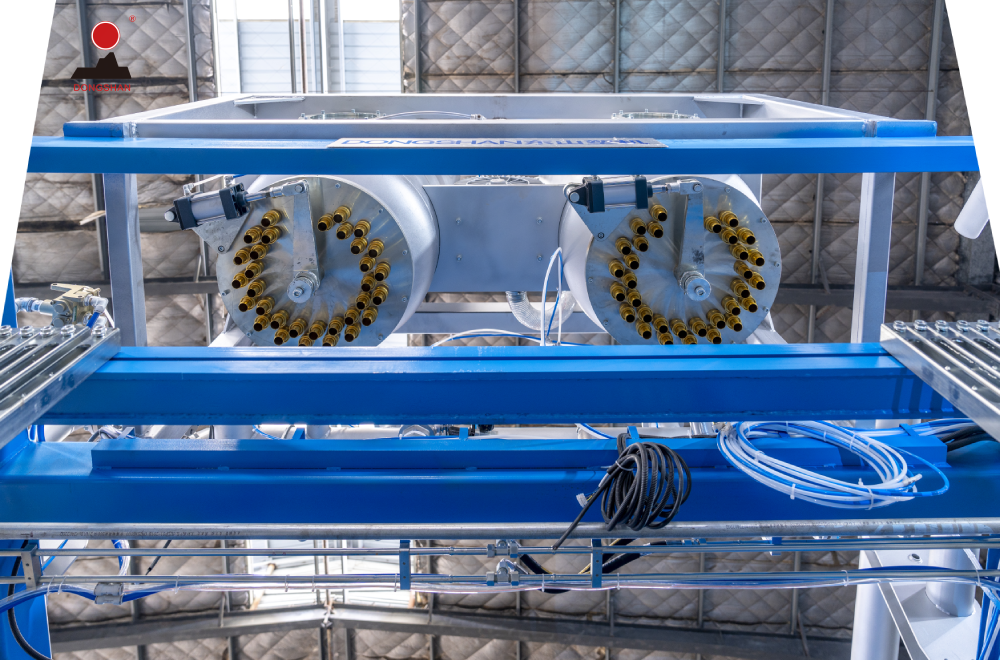

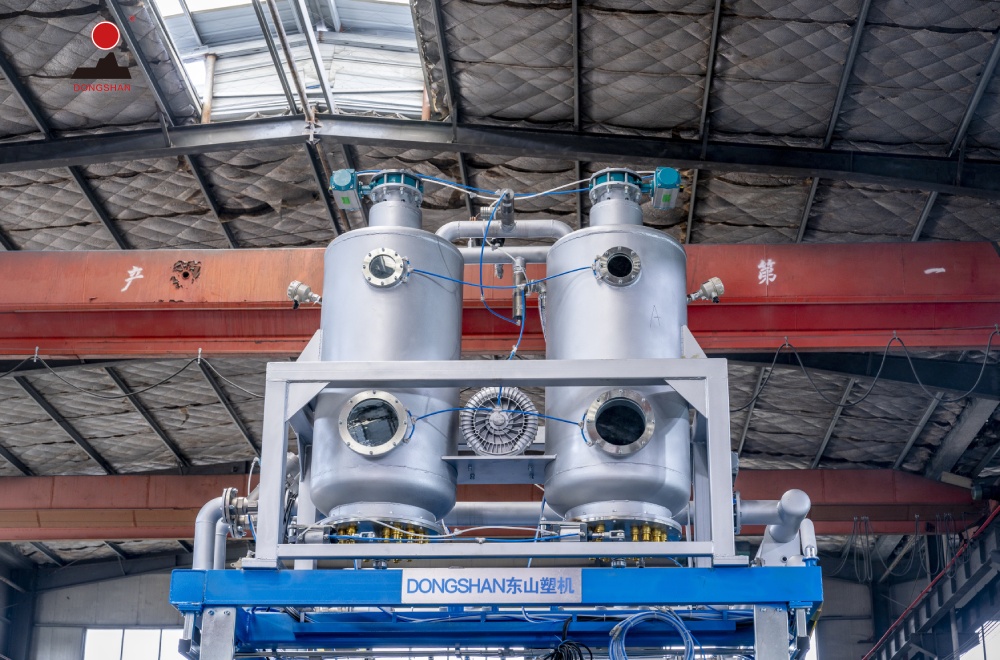

Barrel System Features

- Barrel Volume: 0.15 m³ (EPP813), 0.3 m³ (EPP1214 & EPP1318)

- Material Supply Fan: 2.2 Kw (EPP813), 3 Kw (EPP1214 & EPP1318)

- Discharge Ports: 32 pcs (EPP813), 50 pcs (EPP1214 & EPP1318)

- Single Machine Vacuum Pump: 5.5 Kw (EPP813), 7.5 Kw (EPP1214 & EPP1318)

- Single Machine Power: 15.2 Kw (EPP813), 21.5 Kw (EPP1214 & EPP1318)

Overall Dimensions and Weight

- Dimensions (L×W×H): 5200X2900X3100 mm (EPP813), 5500X3000X3700 mm (EPP1214), 5800X3400X3800 mm (EPP1318)

- Single Machine Weight: 10 T (EPP813), 13 T (EPP1214), 15 T (EPP1318)

With a comprehensive range of technical specifications and robust manufacturing standards, our EPP foam plastics machines are engineered to meet diverse industrial needs, ensuring quality and efficiency in every operation.