EPP Foam Production: Automatic Compression Molding Machine

Advanced EPP Molding Machines for Diverse Applications

Our EPP (Expanded Polypropylene) molding machines are engineered to press EPP particles into precise shapes using advanced heating, injection, and cooling techniques. These machines are essential in producing high-quality components for automotive parts, sports equipment, and premium packaging.

Key Technical Specifications

- Models Available: EPP813, EPP1214, EPP1318

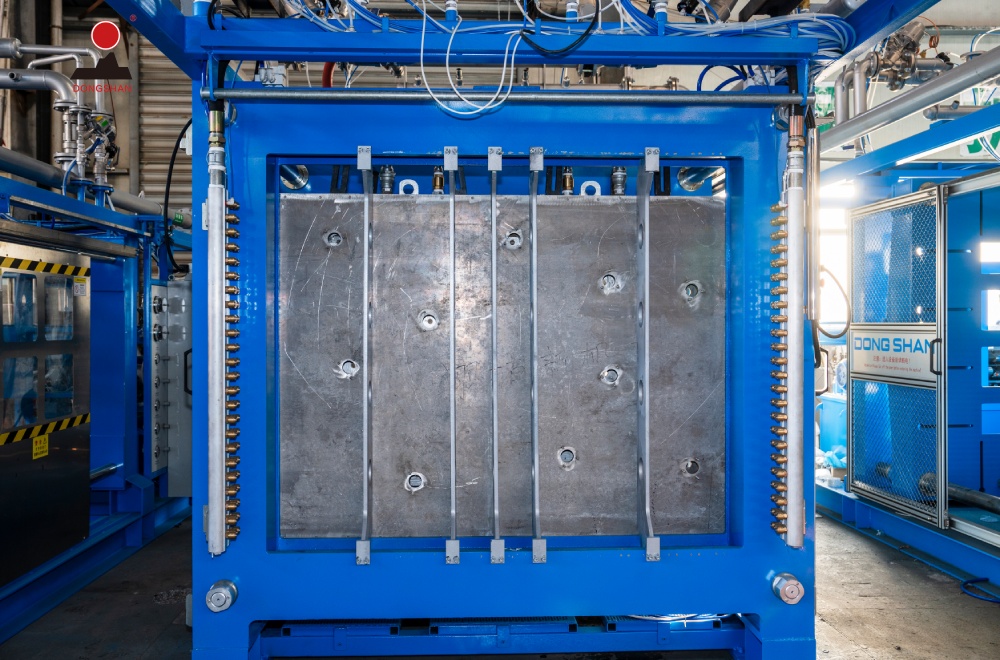

- Mold Frame Dimensions: 1430x930 mm, 1530x1330 mm, 1930x1430 mm

- Effective Molding Area: 1200x700 mm, 1300x1100 mm, 1700x1200 mm

- Maximum Product Height: 400 mm for all models

Integrated Systems for Optimal Performance

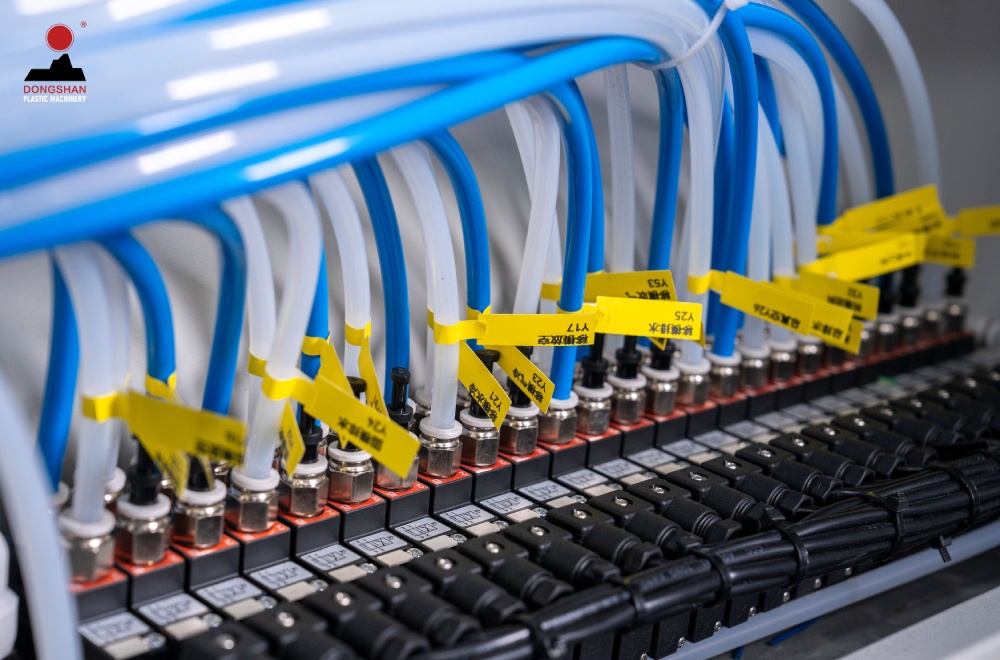

Our EPP molding machines are equipped with advanced systems to ensure seamless operation:

- Steam System: Features a working pressure of 5-8 Kg/cm² with steam pipelines of DN 100-125.

- Air System: Pipelines with DN 65-80 and working pressure between 4-5 Kg/cm².

- Cooling Water System: DN 80-100 pipelines operating at 3-4 Kg/cm².

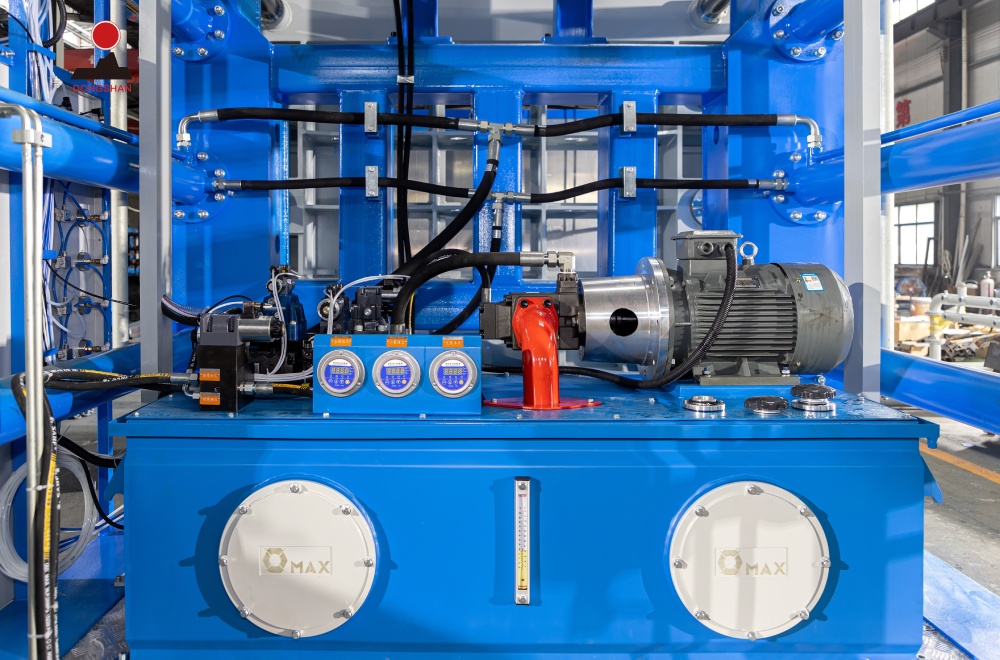

- Hydraulic System: Includes oil pump motors of 7.5-11 Kw, delivering maximum clamping force of 50-100 T.

Innovative Design for Efficiency and Ease

Our machines boast a fully automatic system designed for efficient foam production, ensuring accuracy and consistency. With compatibility for various mold specifications, these machines are energy-efficient, simple to operate, and significantly enhance production efficiency while minimizing labor costs.

Industry Applications

These machines serve multiple industries, including electronics, electrical appliances, and packaging, providing a reliable solution for high-demand production lines.

Dimensions and Power

- Overall Dimensions: Models range from 5200x2900x3100 mm to 5800x3400x3800 mm.

- Single Machine Weight: Between 10-15 T, ensuring stability.

- Single Machine Power: Ranges from 15.2-21.5 Kw, optimized for performance.