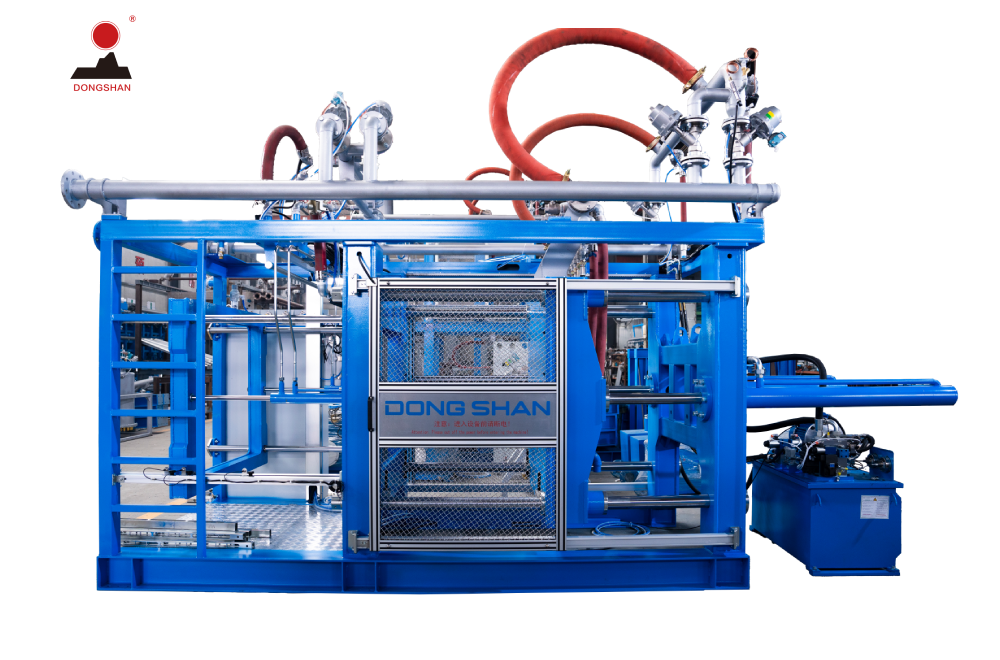

EPP High-Speed Auto Shape Molding Machine

Technical Specifications for Advanced EPP Molding Machines

Upgrade your production line with our state-of-the-art EPP molding machines, available in three models: EPP813, EPP1214, and EPP1318. These machines are designed for maximum efficiency, precision, and versatility in all your molding needs.

Mold Frame Dimensions and Rear Window Size

- EPP813: Mold Frame - 1430x930 mm, Rear Window - 1350x850 mm

- EPP1214: Mold Frame - 1530x1330 mm, Rear Window - 1450x1250 mm

- EPP1318: Mold Frame - 1930x1430 mm, Rear Window - 1850x1350 mm

Effective Molding Area and Maximum Product Height

- EPP813: 1200x700 mm area, Max Height - 400 mm

- EPP1214: 1300x1100 mm area, Max Height - 400 mm

- EPP1318: 1700x1200 mm area, Max Height - 400 mm

Efficient Steam, Air, and Cooling Water Systems

Our machines feature robust steam, air, and water systems designed to enhance performance and energy savings.

- Steam Pipeline: DN 100-125, Working Pressure: 5-8 Kg/cm²

- Air System: DN 65-80, Working Pressure: 4-5 Kg/cm²

- Cooling Water: DN 80-100, Working Pressure: 3-4 Kg/cm²

Sewage and Hydraulic Systems for Smooth Operations

- Sewage System: Includes Vacuum Interface, Fixed/Movable Drainage, and Mold Interface

- Hydraulic System: Delivers a Maximum Clamping Force of 50-100 T

Barrel System and Power Specifications

- Barrel Volume: 0.15-0.3 m³

- Material Supply Fan: 2.2-3 Kw

- Single Machine Power: 15.2-21.5 Kw

Key Features for Optimal Performance

- Multiple feeding methods - pulse, normal pressure, pressurized, and more

- High-precision digital proportional valve for energy efficiency

- Intensive hydraulic drive system for easy maintenance

- Rail-type quick mold change structure for reduced downtime

- Water tank and insulated steam chamber for improved safety

- High-rigidity frame suited for long-term EPP production

Our EPP molding machines offer a comprehensive solution that enhances productivity, reduces energy consumption, and adapts to the high standards of the EPP industry.