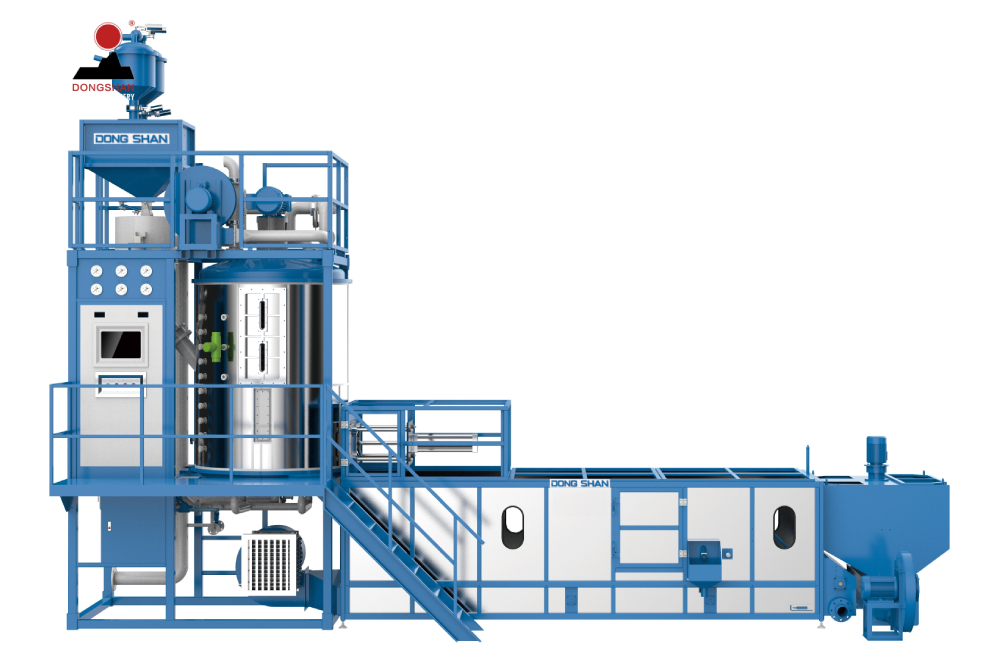

EPS Advanced Automatic Pre-Expander Machine

Advanced Frequency Spindle and Steam System

The frequency spindle allows for adjustable spindle rotation speed tailored to different raw material processes. This ensures precise control over the expanding weight. The steam system incorporates a high-quality relief valve from YOSHITAKE, Japan, with a high-precision drainage valve and filter, guaranteeing stable steam pressure.

Pressure and Temperature Control for Optimal Expansion

Utilizing international pressure sensors, German BATTON angle-seat valves, and a multi-valve exhaust system, our equipment maintains constant temperature and pressure for stable and accurate expansion. Temperature control is achieved with the help of international temperature sensors and German BATTON dual proportional valves for both steam and air.

Precision Weighing and Feeding System

An electronic weighing system is in place for accurate feeding. The desired feeding weight can be easily set up on the touch screen, and the weighing device automatically ensures precise material feeding.

Material Management and Fluidizer Bed Features

- Equipped with Korean vibration sensors for precise control of expanding material levels, ensuring uniform particle density.

- The height of the material level in the fluidizer bed is adjustable to enhance the aging effect of expanded particles.

- A flap feeding device in the fluidizer bed ensures efficient particle feeding.

- The crushing device at the bottom of the fluidizer bed allows for easy cleaning.

Optional Features

- Automatic density weighing system.

- Optional second expandable functions for X-MAX1400 and X-MAX1670 models.

Technical Specifications

| Item | Unit | X-MAX1100B | X-MAX1400B | X-MAX1670B |

|---|---|---|---|---|

| Expand Chamber | mm | Φ1100×1700 | Φ1400×1800 | Φ1670×2240 |

| Volume | m3 | 1.3 | 2.7 | 4.8 |

| Motor Power | Major Motor (Kw) | 5.5 | 7.5 | 11 |

| Capacity: 12 Kg/m3 | Kg | 320 | 640 | 960 |

Hangzhou Fuyang Dongshan Plastic Machinery Co., Ltd. specializes in manufacturing EPS and EPP foam plastics machines. With nearly 20 years of experience in independent R&D, manufacturing, sales, and service, we ensure high-quality products and customer satisfaction.