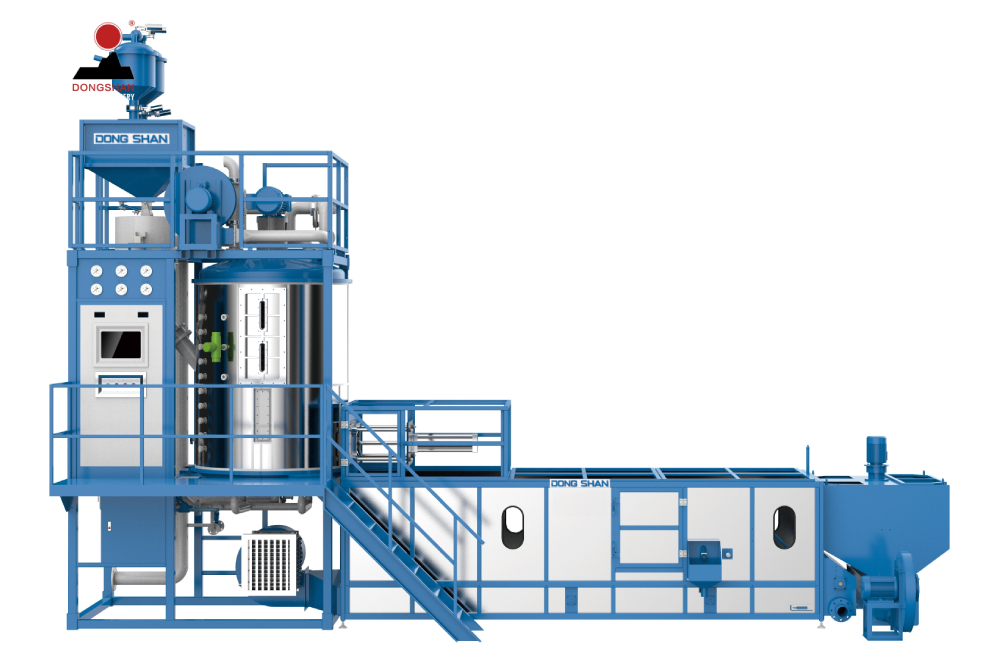

EPS Automatic Pre-Expander with Precise Material Control

Introduction to Machine Functions and Characteristics

Dongshan's EPS Intelligent Automatic Pre-Expander with Precise Material Control provides efficient, intelligent, and stable EPS pre-foaming solutions suitable for various batch production needs. This machine is engineered to offer numerous advantages, including precise material control, intelligent operating system, fully automated production, and energy efficiency.

Key Features of the Machine

- Material Control Precision: Automatically adjusts the raw material feed amount to achieve uniform density and a stable foaming effect.

- Intelligent Operating System: User-friendly interface ensures easy operation and quick learning curve.

- Fully Automated Production: Minimizes manual intervention to boost production efficiency and stability.

- Energy Efficiency: Optimizes the foaming process to reduce energy consumption and overall production costs.

Technical Specifications

- Construction: Barrel body constructed with mirror stainless steel for a smooth, material-free inner wall. Frame and main body are plastic-sprayed for enhanced wear and corrosion resistance.

- High Precision: CNC processing ensures an overall high precision design, resulting in stable and durable shafting.

- Heating System: Conical feeding barrel rotates 360° for rapid and uniform foaming; equipped with imported proportional valves for precise pressure and temperature control.

- Motor System: Main shaft reducer features a K97 type motor with a Mitsubishi inverter for high output torque suitable for diverse raw materials.

- Control System: Siemens PLC control system with Ethernet interface enables seamless integration with MBS systems.

- Safety and Monitoring: Vibration sensors from Germany ensure accurate material level control and have monitoring and early warning systems to prevent extreme scenarios.

Application and Usage

This state-of-the-art machine is ideal for high-precision EPS sheet and block production, ensuring the consistency of subsequent molded products. Its closed-loop intelligent control system allows for precise pre-distribution of EPS beads, maintaining particle size uniformity of over 95% and density fluctuation under 3%. This significantly reduces labor and energy costs while providing high-stability pre-foaming solutions for packaging, building materials, and the cold chain industry.

Machine Models and Capacities

- Model X-MAX1100B: Expand chamber size: Φ1100×1700 mm, Volume: 1.3 m3, Effective volume: 1 m3, Motor power: 5.5 kW, Capacity at 12 Kg/m3: 320 Kg

- Model X-MAX1400B: Expand chamber size: Φ1400×1800 mm, Volume: 2.7 m3, Effective volume: 2 m3, Motor power: 7.5 kW, Capacity at 16 Kg/m3: 840 Kg

- Model X-MAX1670B: Expand chamber size: Φ1670×2240 mm, Volume: 4.8 m3, Effective volume: 3.5 m3, Motor power: 11 kW, Capacity at 20 Kg/m3: 1500 Kg