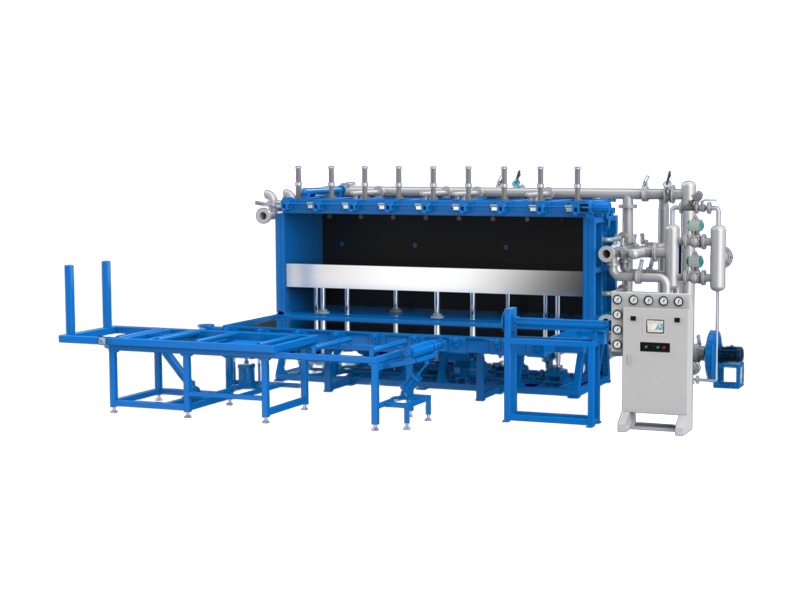

EPS Block Molding Machine for Polystyrene Panels

EPS Foam Molding Machines for Superior Production

The EPS foam molding machines are engineered to deliver high-quality expanded polystyrene (EPS) products, including insulation boards, foam sheets, and EPS molded boards. Designed to meet the unique requirements of building energy conservation, packaging materials, and industrial applications, these machines ensure exceptional performance and versatility.

Product Specifications

- Mould Cavity Size (mm): Available in sizes ranging from SPB2000LZ (2040×1240×1030) to SPB6000LZ (6080×1240×1030).

- Block Size (mm): From 2000×1200×1000 to 6000×1200×1000, tailored for different project needs.

- Steam & Air Specifications: Efficient steam and compressed air systems with varying inlet dimensions and consumption metrics.

- Pressure: Consistent operational pressure across all models to maintain product integrity.

- Energy Efficient: Steam consumption ranges from 70 to 180 Kg/Cycle, promoting energy conservation.

- Production Time: Cycle times from 6 to 12 minutes depending on the model, optimizing workflow efficiency.

- Connected Load/Power (Kw): Between 13/28 and 16.5/28.5, catering to varied production scales.

- Overall Dimensions (mm): Models available from 6700×4600×4100 to 6700×4600×8100.

- Weight (Kg): From 12,200 for the SPB2000LZ to 19,500 for the SPB6000LZ.

Key Features

- Multi-functional Production: Support for multiple product specifications, including panels, sheets, and plates.

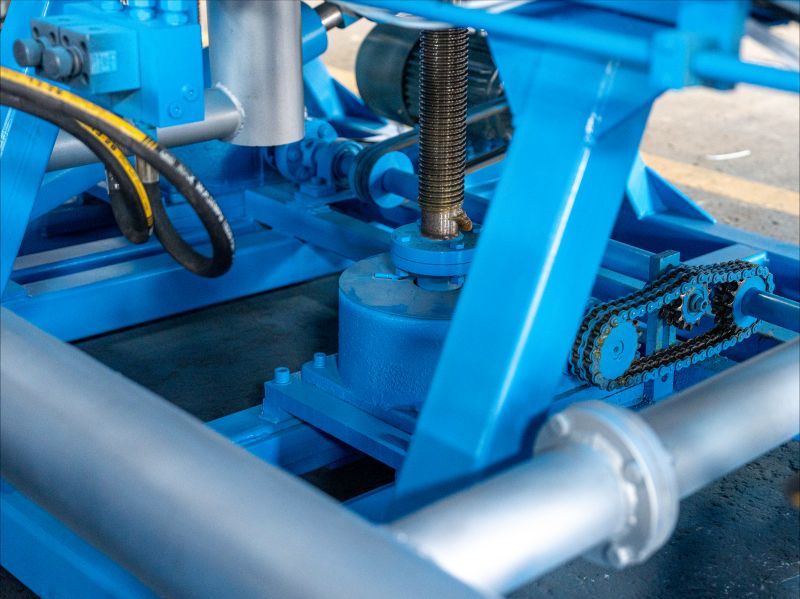

- High-Precision Forming: Guarantees stable product sizes and consistent quality.

- Automated Control: Minimizes manual labor and enhances production efficiency.

- Energy Conservation & Environmental Protection: Advanced steam and energy management to cut costs and minimize waste.

Experience unparalleled efficiency and quality with our EPS foam molding machines, designed to cater to diverse industrial and construction needs with precision and reliability.