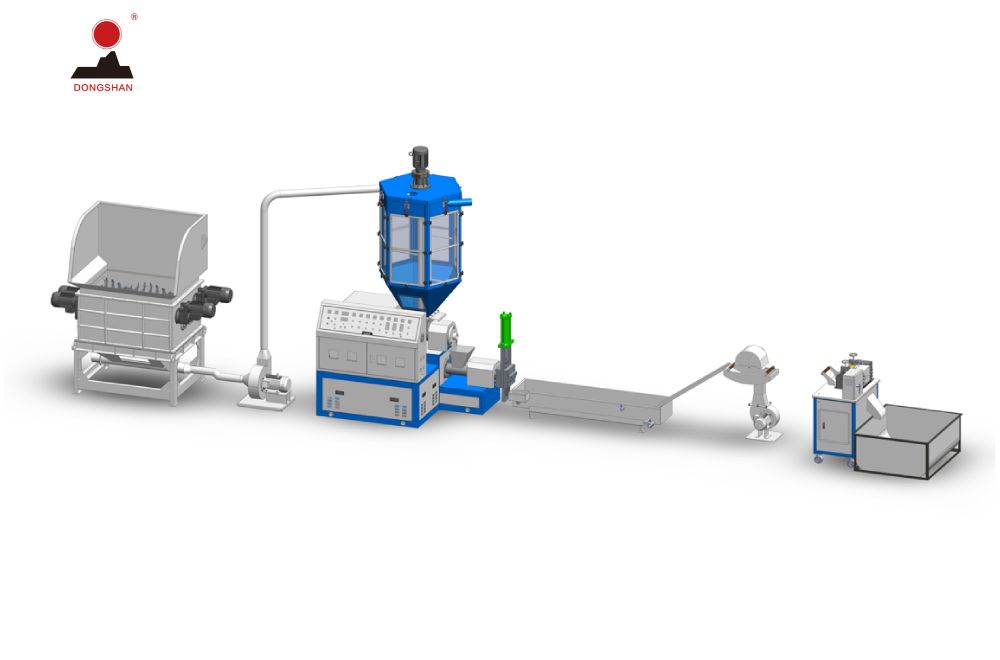

EPS Foam Recycling Machine: Efficient Pelletizer Solution

Advanced EPS Foam Pelletizing Solutions

Our state-of-the-art EPS foam granulators are engineered to recycle used foam and scraps efficiently. By transforming EPS waste into uniform and stable recycled particles, these machines support sustainable production and cost reduction in raw material acquisition.

Product Models & Specifications

-

Model: DSSJ-SJP-160-95

- Function: EPS foam pelletizing

- Capacity: 60-100kg/h

- Price: $21,000 (New crusher extra: $3,000)

-

Model: DSSJ-SJP-185-105

- Function: EPS foam pelletizing

- Capacity: 100-150kg/h

- Price: $23,000 (New crusher extra: $3,200)

-

Model: DSSJ-SJP-220-120

- Function: EPS foam pelletizing

- Capacity: 150-200kg/h

- Price: $29,000 (New crusher extra: $3,800)

-

Model: DSSJ-SJP-250-125

- Function: EPS/XPS foam pelletizing

- Capacity: 200-250kg/h

- Price: $31,000 (New crusher extra: $4,000)

Key Features

- Efficient Recycling: Rapid processing capability for EPS waste, ensuring stable production and minimized workshop pile-up.

- Energy-saving Design: Optimized heating and extrusion systems to cut down energy consumption significantly.

- Convenient Operation: Compact structure with easy maintenance for long-term continuous production.

- Environmental Benefits: Facilitates EPS recycling, supporting green production initiatives.

Technical Details

Each model is powered by advanced technology components to ensure optimal performance:

- Crusher Motor Power Options: 5.5kw-4p, 11kw-4p, or 15kw-4p

- Convey Blower Motor Power: Ranges from 3.0Kw-2P to 5.5Kw-2P with pipe

- Main Extruder: Equipped with ceramic heaters and high-quality 45# material screws and barrels

- Water Tank: All stainless steel, with lengths varying from 2000mm to 3000mm

- Control Systems: Advanced control boxes for seamless operation

Our EPS foam granulators are designed to maximize efficiency, reduce costs, and promote sustainability in manufacturing processes. Choose the model that best suits your production needs and join the movement towards sustainable production practices.