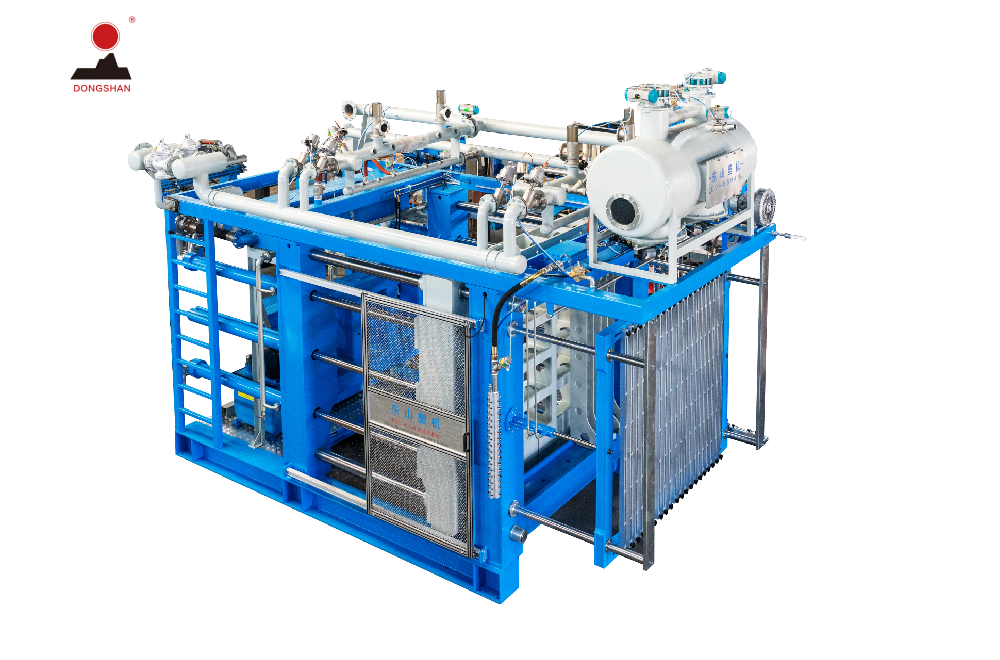

Fully Automatic EPS Shape Molding Machine for Packaging

Advanced EPS Fully Automatic Shape Molding Machine

The EPS Fully Automatic K-Type Shape Molding Machine is a state-of-the-art solution engineered to deliver efficient and stable foam molding production. Designed for diverse applications such as electrical packaging, building insulation materials, and customized EPS products, this machine caters to multiple mold sizes, ensuring high versatility and performance.

Key Features of EPS Shape Molding Machine

- Fully Automatic Operation: Minimize manual intervention to boost production efficiency.

- Stability and Reliability: Guarantees product molding consistency and superior quality.

- Energy-Saving Design: Optimizes energy consumption, reducing overall production costs.

- Versatile Usage: Ideal for packaging products, building insulation boards, and customized EPS parts.

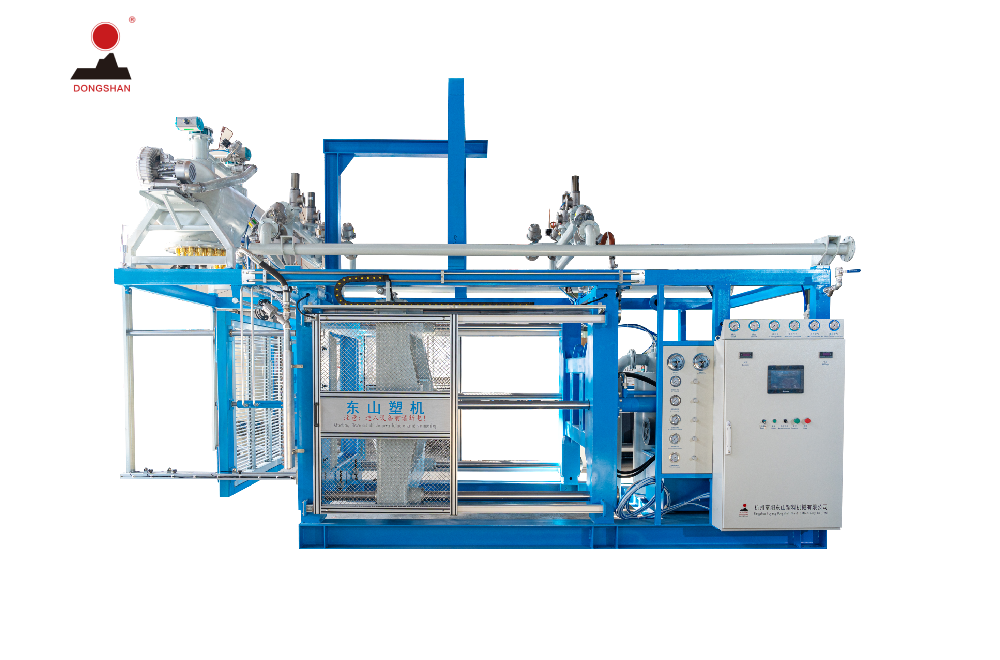

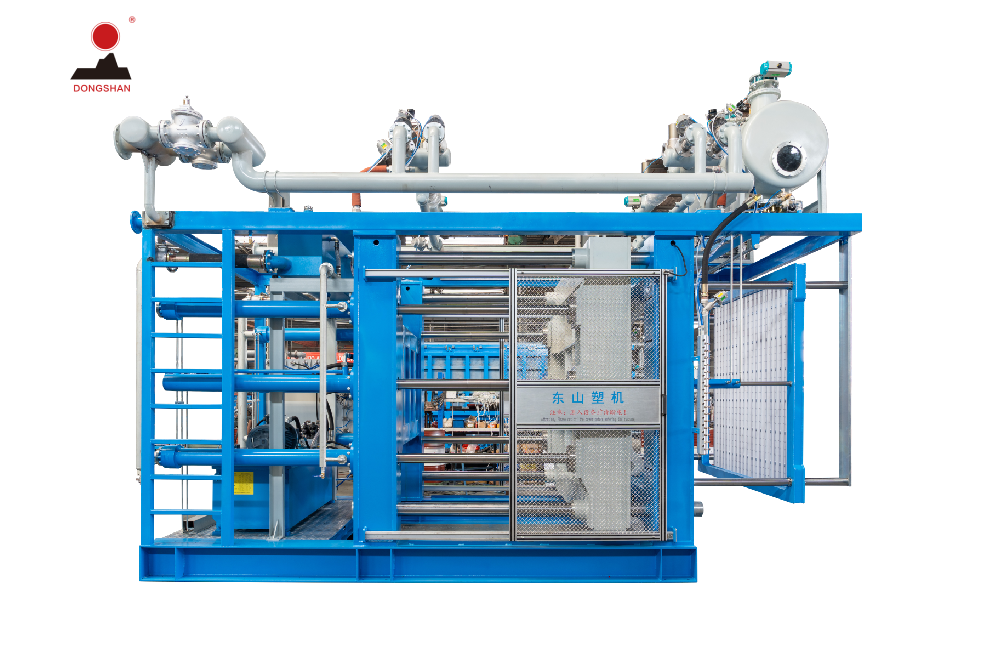

Technical Specifications

- Outer Dimension Sizes (L×W×H): Ranges from 5250×1750×3785 mm to 5632×2620×4100 mm.

- Effective Forming Area: 1000×800 mm to 1950×1350 mm.

- Maximum Clamping Force: 24 T to 42 T.

- Barrel Material Capacity: 0.15 m³ to 0.3 m³.

- Weight: 4.5 T to 9 T.

Enhanced Production Specifications

- Steam Pipeline: DN 100 to DN 125 with working pressure of 3~6 Kg/cm².

- Cooling Water Pipeline: DN 80 to DN 100 with working pressure of 3~4 Kg/cm².

- Hydraulic Oil Pump Motor: Capacity ranges from 5.5 Kw to 11 Kw.

- Material Supplementary Blower Power: 1.5 Kw to 2.2 Kw.

- Single Motor Power: 7 Kw to 13.2 Kw.

Leverage the advanced capabilities of the EPS Fully Automatic K-Type Shape Molding Machine to enhance your production line efficiency and product quality. Its robust design ensures long-term reliability and adaptability to various industrial needs.