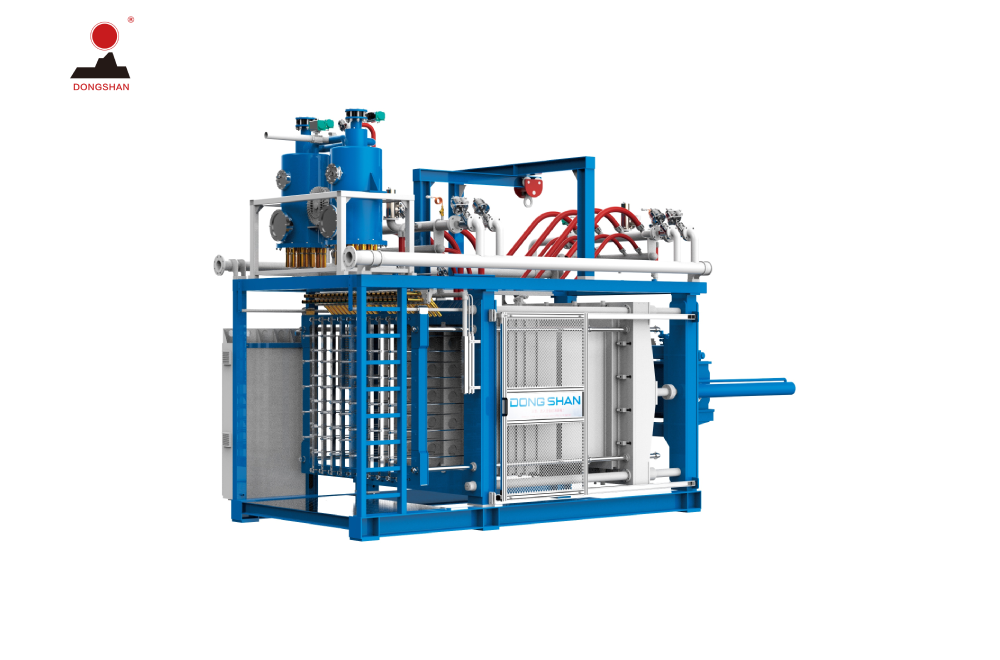

Fully Automatic EPS X-B Shape Molding Machine

Innovative Equipment Features: Enhancing Durability and Precision

Our advanced equipment utilizes cutting-edge CNC blanking technology for all steel blanking processes, complemented by galvanizing treatment to enhance part longevity and surface quality. The incorporation of South Korea's Autonics encoder ensures precision in the equipment's running stroke, supported by a redesigned self-balancing encoder bracket for enhanced safety and reliability.

Key Advantages

- Stress-Free Welding: All welding parts undergo electric furnace stress relief annealing and CNC machining, ensuring structural precision, concentricity, and long-term operational stability.

- Efficient Demoulding: The latest movable ejector fixed support design addresses maintenance issues promptly, boosting work efficiency and safety.

- Guide Post Precision: Chrome-plated 45# steel guide posts and CNC-formed guide sleeves guarantee installation accuracy.

- Hydraulic System Excellence: Featuring a modern design and imported control parts, the hydraulic system’s stability and operation speed are significantly improved with differential valves.

- Enhanced Maintenance: New oil cylinder design allows for easy maintenance, enhancing work efficiency and safety without full disassembly.

Advanced Systems

Our equipment boasts sophisticated systems to ensure superior performance:

- Pressure Control: German Gemi double valves and American MAC high-frequency valves, paired with German WIKA pressure sensors, enable precise and stable control of mold cavity pressure.

- Vacuum System: Dual eccentric butterfly valves ensure timely formation of vacuum negative pressure, improving efficiency with minimal water content.

- Valve System Precision: The combination of German Burkert solenoid valves and Japanese SMC precision filters enhances control sensitivity and stability.

- User Interface: A 15.6-inch high-definition LCD touchscreen with remote transmission capabilities facilitates user convenience in collecting production data.

Technical Specifications

Our equipment is designed to meet a variety of technical needs, ensuring seamless operation across different applications:

- Application Technical Data: Available models include EPS1210, EPS1412, EPS1513, EPS1750, EPS1816, and EPS2216, each designed with specific dimensions and capabilities.

- Steam and Air Pipeline Interfaces: Sizes range from DN 100 to DN 125, supporting working pressures of 3 to 6 Kg/cm² (steam) and 4 to 5 Kg/cm² (air).

- Hydraulic System Specifications: Hydraulic oil pump motors range from 5.5 Kw to 11 Kw, with maximum clamping forces from 24 T to 42 T.

Customer Success Stories

Our equipment is designed for scientific operation, robust structural integrity, and advanced system integration, ensuring high temperature resistance and precision in every application. Equipped with a self-closing exhaust feeding gun, our systems provide efficient and precise control for superior performance.