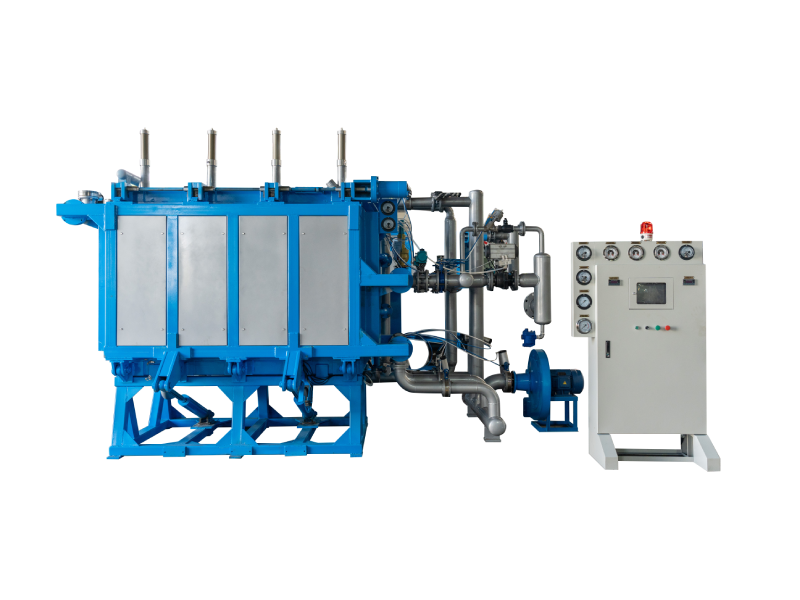

High-Efficiency DS 200-600 EPS Foam Block Machine

Advantages of Plate Machine Equipment

Plate machine equipment is designed with optimized performance, focusing on four key areas: safety, quality, efficiency, and energy conservation. Below is a detailed breakdown of the benefits in each category.

Safety Features

- 4-Fold Protection System:

- Electric contact pressure gauge on the equipment body with a pressure limit of 1.2bar.

- Electric contact pressure gauge on the control box has a pressure limit of 0.5-0.8bar.

- Safety valve on the equipment body with a pressure limit of 2bar.

- Dual Control: The system has two pressure sensors and an electric contact pressure gauge for enhanced safety and stability.

- Robust Locking Devices: Front and side locking devices are strengthened with thick rods and quenched pins to ensure durability and better sealing.

- Advanced Control System: Equipped with a Japan Mitsubishi FX3U series programmable controller and Taiwan Weilun touch screen for precise process adjustments and real-time monitoring.

Quality Perspective

- Expansion Coefficient Pressure Sensor: Ensures digital control for board machine door opening, preventing waste boards and ensuring stable production.

- Special Material Seals: Uses PTFE (Teflon) for excellent chemical stability, sealing, and corrosion resistance.

- Improved Steam Inlet Valve: Double eccentric metal sealing butterfly valve enhances sealing performance and longevity.

- Durable Structure: Made with high-quality square tubes and processed for enhanced rigidity and extended service life.

- Efficient Hydraulic System: High-speed, high-pressure design with fast mold opening and closing, ensuring plate integrity during ejection.

Efficiency Benefits

- Automatic Weighing and Conveying: Includes an optional extended conveying system for seamless production.

- Remote Monitoring: Allows for quick troubleshooting and parameter adjustments from a remote location.

- Optimized Material Gun Arrangement: Ensures faster feeding speed with tailored configurations for different plate machines.

- Effective Vacuum System: Reduces moisture content and saves steam energy by 5-10%.

Energy Conservation

- Steam-Water Separator: Minimizes steam moisture content for better steam penetration efficiency.

- Efficient Heating System: Maintains stable production with minimal steam consumption.

- Vacuum Cooling: Enhances rapid demoulding and reduces energy consumption for subsequent molding processes.

The DS200-600 EPS foam plate forming machine exemplifies these attributes, offering high precision, capacity, and automated temperature control for consistent performance. This equipment meets the needs of building insulation, packaging, and industrial product sectors, contributing to improved operational efficiency and reduced labor costs.