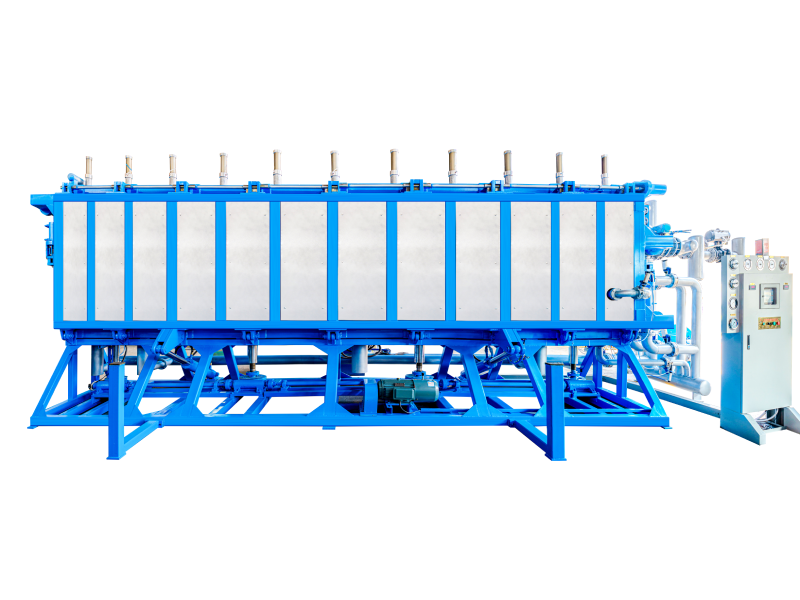

High-Efficiency EPS Foam Plate Vacuum Former

High-Precision EPS Foam Board Vacuum Forming Machines

Our Dongshan EPS foam board vacuum forming machines are engineered for producing precise polystyrene boards, ideal for building insulation, packaging, and industrial products. These machines ensure consistent quality, streamline operations, and boost productivity with ease.

Specifications and Features

- Mould Cavity Sizes (mm):

- SPB2000LZ: 2040 × 1240 × 1030

- SPB3000LZ: 3060 × 1240 × 1030

- SPB4000LZ: 4080 × 1240 × 1030

- SPB6000LZ: 6080 × 1240 × 1030

- Block Sizes (12g/L) (mm):

- SPB2000LZ: 2000 × 1200 × 1000

- SPB3000LZ: 3000 × 1200 × 1000

- SPB4000LZ: 4000 × 1200 × 1000

- SPB6000LZ: 6000 × 1200 × 1000

Energy Efficiency and Consumption

- Steam Inlet: 4-8 with consumption ranging from 70-180 Kg/Cycle

- Compressed Air Inlet: 3-4 with consumption from 1.5-4.5 M³/Cycle

- Vacuum Inlet: 2-3”

- Cooling Water Consumption: 0.6-1.4 Kg/Cycle

Connectivity and Operation

- Drainage: Drain Outlet 5-8, Air Outlet 6-8, Vacuum Drain Outlet 4-5

- Production Time: 6-12 min/Cycle for 12g/L density blocks

- Connected Load/Power: 13/28 - 16.5/28.5 Kw

Dimensions and Weight

- Overall Dimensions (L×W×H) (mm): 6700 × 4600 × 4100 to 8100

- Weight (Kg): 12200 - 19500

Designed for stability and speed, the Dongshan EPS foam board vacuum forming machine streamlines production, ensuring consistent board dimensions and superior quality with user-friendly operation.