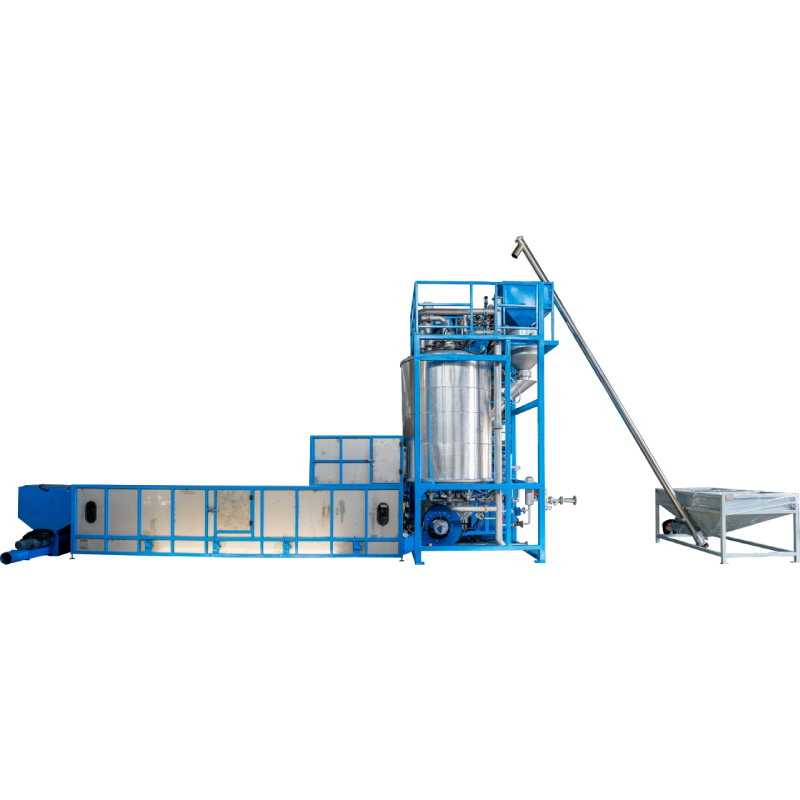

High-Efficiency EPS Pre-Expander 1400 Machine

Advanced Control Systems for Optimal Performance

Our cutting-edge EPS fully automatic batch pre-expander is designed with a sophisticated Control System PLC and intuitive human-touch interface for seamless operation. Enjoy the convenience of automatic processes, minimal maintenance, and swift working process changes with built-in computer memory functions.

Innovative Structure Design for Efficient Processing

- Weighing System Placement: Located on top of the barrel for optimal balance and precision.

- Hot Air Drying: High-quality closed hot air drying system maximizes drying efficiency and effectiveness.

- Long-lasting Durability: Components and fittings are sourced from reputable brands, ensuring a long service life.

Technical Specifications

- Expansion Chamber Diameter: DN1400 & DN1660

- Volume Capacity: 2.1 m³ & 4.8 m³

- Steam Consumption: 8-10 kg/cycle & 11-14 kg/cycle

- Compressed Air Consumption: 0.5-0.8 m³/cycle & 0.7-1.1 m³/cycle

Capacity and Efficiency

- Diverse Density Processing: Capable of handling densities from 4g/L to 20g/L efficiently.

- High-Volume Output: Production capacities reach up to 820 and 1500 units at 20g/L density.

- Energy-Efficient Operation: With a connected load of 22.5 Kw and 24.5 Kw.

Precision and Reliability in Foam Production

This state-of-the-art equipment ensures uniform expansion and efficient EPS particle processing, making it an excellent choice for large-scale foam production. With intelligent control systems for continuous production and precise temperature control, it guarantees consistent density and quality in EPS packaging, architectural foams, and electronic product buffers.

Dimensions and Weight

- FDS1400Ⅰ―Ⅱ: 6500mm x 4500mm x 4500mm, Weight: 4500 kg

- FDS1600Ⅰ―Ⅱ: 9000mm x 3500mm x 5500mm, Weight: 4800 kg

Enhance your production capabilities with this efficient, energy-saving, and reliable pre-expansion solution tailored for modern EPS foam manufacturing needs.