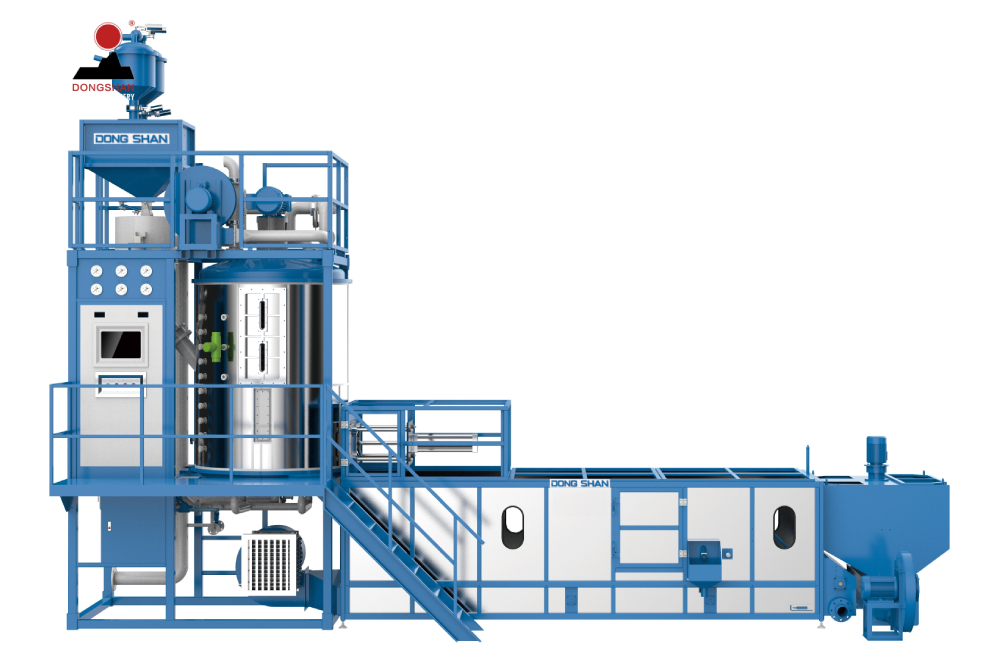

High Efficiency EPS Pre-Foaming Machine - Intelligent Model

Revolutionary EPS Pre-Foaming Machine: X-MAX Series

Introducing the X-MAX series of fully automatic EPS pre-foaming machines, designed for efficiency and intelligence. With advanced automated control systems, these machines manage the entire process of raw material heating, uniform delivery, and stable discharge.

Core Advantages of X-MAX EPS Pre-Foaming Machine

- High-efficiency Operation: Rapidly completes the pre-foaming process, making it ideal for mass production needs.

- Intelligent Control: Features a touch screen operation and data visualization to minimize training costs.

- Energy Saving and Environmental Protection: Optimizes the utilization of steam and electric energy, significantly reducing production energy consumption.

- Versatility: Suitable for producing insulation boards, packaging materials, building fillings, and lightweight foam products.

X-MAX Series Models

X-MAX1100B

- Expand Chamber: Φ1100×1700 mm

- Volume: 1.3 m3 (Effective Volume: 1 m3)

- Steam Inlet: 2"(DN50)

- Motor Power: Major Motor 5.5 Kw, Feeding Motor 4 Kw

- Capacity: 320-650 Kg depending on density

X-MAX1400B

- Expand Chamber: Φ1400×1800 mm

- Volume: 2.7 m3 (Effective Volume: 2 m3)

- Steam Inlet: 2"(DN50)

- Motor Power: Major Motor 7.5 Kw, Feeding Motor 4 Kw

- Capacity: 640-1250 Kg depending on density

X-MAX1670B

- Expand Chamber: Φ1670×2240 mm

- Volume: 4.8 m3 (Effective Volume: 3.5 m3)

- Steam Inlet: 2"(DN50)

- Motor Power: Major Motor 11 Kw, Feeding Motor 5.5 Kw

- Capacity: 960-1850 Kg depending on density

Engineered for EPS product manufacturing, the X-MAX series is a preferred choice for companies aiming for efficient and cost-effective production both locally and globally.