High-Efficiency Foam Granulator Machine

Advanced Waste Foam Recycling Solutions

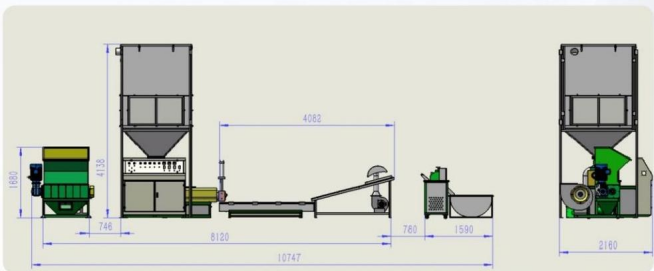

Transform waste foam into valuable materials with our comprehensive production line. From foam crushing to hot melting, extrusion, cooling, and cutting, our advanced technology allows for efficient conversion into polystyrene (PS).

Innovative Twin-Screw System

- Primary screw hot melt followed by secondary screw extrusion.

- Automatic hydraulic net change minimizes wire breakage for seamless production.

High Efficiency Crushing System

Equipped with a large-volume powder silo and frequency conversion, our system significantly enhances production efficiency. Enjoy a stable and sufficient feed for consistent extruded particle uniformity.

Durable and Reliable Components

- The secondary screw features 38CrMoAl material for longevity.

- Tempering treatment applied to both primary and secondary screws for extended service life.

- All electrical components are from the Schneider brand, ensuring stable quality and easy debugging and installation.

Model Specifications

- Model PS-90-S: Yield of 60-70 kg/hour, featuring a screw size of 160*200*640 and a total power of 51 KW.

- Model PS-100-M: Yield of 120-150 kg/hour, screw size of 185*225*750, and total power of 67 KW.

- Model PS-125-L: Yield of 180-220 kg/hour, with a screw size of 250*280*1150 and total power of 130 KW.

About Us

Hangzhou Fuyang Dongshan Plastic Machinery Co., Ltd. has nearly 20 years of experience in manufacturing EPS and EPP foam plastics machinery. We integrate independent research and development, manufacturing, sales, and service to offer cutting-edge solutions.