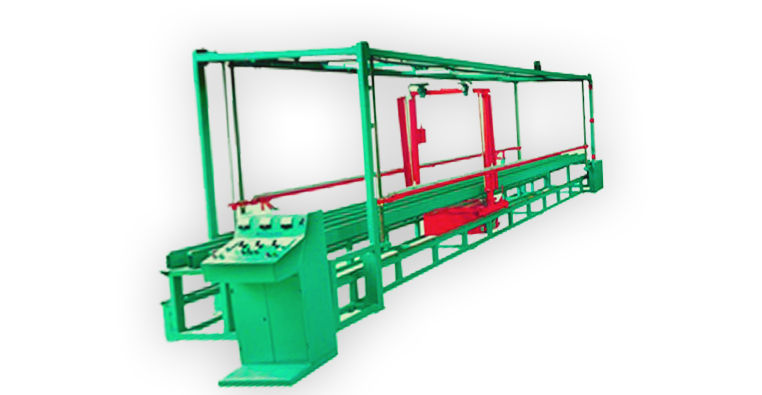

High-Efficiency SPC Series Crushing Machine

Technical Data: SPC Series Crushers for EPS and Foam Materials

The SPC series crushers are engineered to efficiently process EPS and other foam materials. Designed for optimal material recycling and secondary utilization, these crushers are ideal for foam board processing plants, packaging product manufacturing, and environmental protection recycling fields.

Features of the SPC Series Crushers

- Durable Blades: Ensure uniform crushing and stable yield.

- Automatic Feeding System: Facilitates seamless operation.

- Simple Operation: Easy to use and maintain.

By integrating the SPC series crushers into your production line, enhance production efficiency and significantly reduce waste treatment costs.

Model Specifications

SPB2000LZ

- Mould Cavity Size: 2040×1240×1030 mm

- Block Size (12 g/L): 2000×1200×1000 mm ×2

- Steam Consumption: 70~100 Kg/Cycle

- Produce Time: 6 min/Cycle

- Weight: 12200 Kg

SPB3000LZ

- Mould Cavity Size: 3060×1240×1030 mm

- Block Size (12 g/L): 3000×1200×1000 mm ×2

- Steam Consumption: 100~130 Kg/Cycle

- Produce Time: 7 min/Cycle

- Weight: 14800 Kg

SPB4000LZ

- Mould Cavity Size: 4080×1240×1030 mm

- Block Size (12 g/L): 4000×1200×1000 mm ×2

- Steam Consumption: 130~160 Kg/Cycle

- Produce Time: 8 min/Cycle

- Weight: 17200 Kg

Optimize Your Production with SPC Series Crushers

These crushers not only streamline your production processes but also support sustainable practices by minimizing waste. Their incorporation ensures reduced costs and improved productivity, making them a pivotal addition to any facility handling foam materials.