High-Precision CNC EPS Foam Cutter - 2D Machine

High-Precision CNC 2D EPS Foam Cutting Machine

Our advanced CNC 2D EPS foam cutting machine is engineered for precision and efficiency in two-dimensional cutting applications. Designed for the production of EPS sheets, packaging parts, and decorative components, this machine is a vital asset to any EPS processing plant.

Mechanical Features

- Constructed with aluminum alloy for a sleek, clean appearance and stable precision during operations.

- Equipped with a motion stroke protection system to halt operations when exceeding the specified stroke, ensuring safety and equipment longevity.

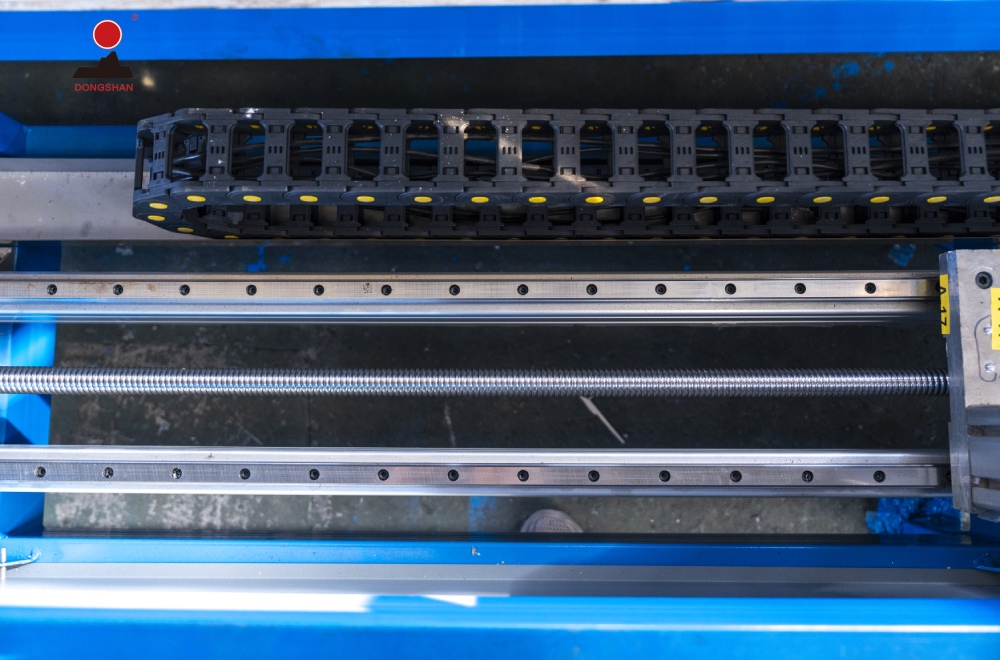

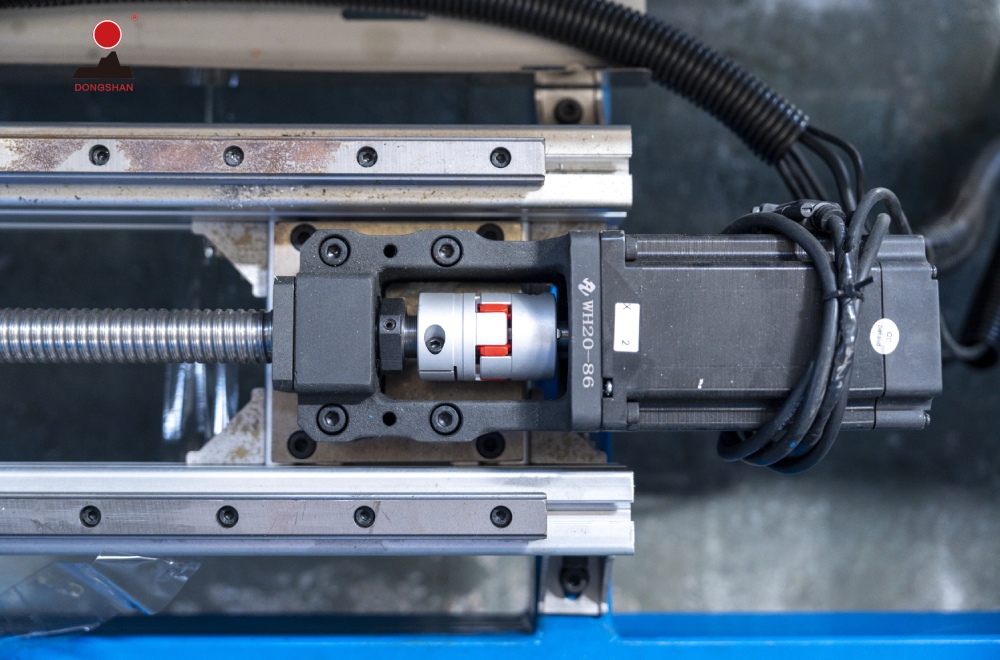

- Utilizes closed-loop stepper motors with synchronization belt drive (or ball screw) for smooth operation and precise speed regulation, allowing for constant speed adjustments and mechanical control accuracy up to 0.05mm.

Control and Software

- Compatible with popular drawing software like AUTOCAD.

- Features a USB Controller for cutting software, supporting file formats such as *.NC and *.DXF.

- Incorporates premium SCHNEIDER electrical components for reliable performance.

- Includes a remote control handle for ease of operation.

- Automatic safety stop when the cutting wire breaks.

- Four travel switch protection for enhanced operational safety.

Technical Data

- Max Net Cut Size: FC200: 2100 × 2100 × 1300 mm, FC250: 2500 × 2100 × 1300 mm, FC200(4 blocks): 2000 × 2100 × 1300 mm

- Cutting Wire Material: φ0.4 G20Ni80

- Max Hot Wire Spec: 12 for FC200, 10 for FC250 and FC200(4 blocks)

- Stepper Motor Torque: 4-8.5 N.M

- Total Capacity: 19 KW

- Cutting Speed Range: 0.3~0.8 m/min

- Voltage Regulator Power: 15 KVA (20 KVA for FC200(4 blocks)), adjustable voltage 0 ~ 220 V

- Cutting Length: FC200 and FC250: 1400 mm, FC200(4 blocks): 3500 mm

- Total Length: FC200: 3200 × 3100 × 2500 mm, FC250: 3200 × 3600 × 2500 mm, FC200(4 blocks): 4580 × 3100 × 2500 mm

- Gross Weight: 700 Kg for FC200, 750 Kg for FC250, 850 Kg for FC200(4 blocks)

Applications

This CNC 2D EPS foam cutting machine supports various graphic and size customizations, catering to diverse needs in building insulation, advertising display, and industrial applications. Its efficient automated control enhances production efficiency while minimizing labor costs, making it an optimal choice for EPS processing plants seeking enhanced productivity and precision.