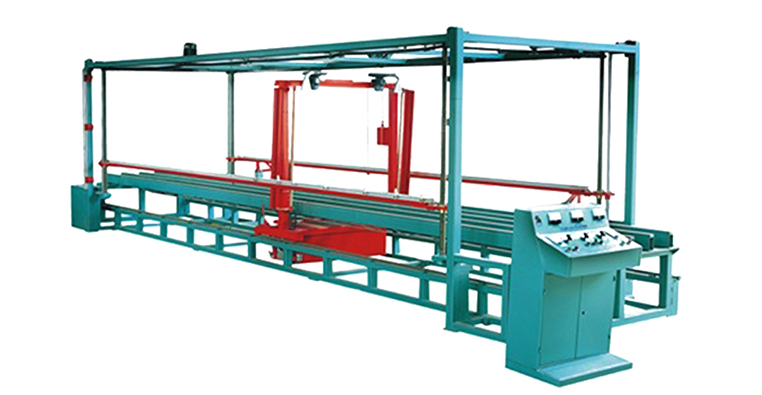

High-Precision EPS Foam Cutting Machine C

Cutting Machine Series (Type C) Control System

The Type C EPS cutting machine is engineered for precision and efficiency, featuring a variable frequency stepless speed regulation. It uses a guide rail drive system to ensure smooth cutting of products. The integrated motor speed reducer further enhances its performance.

Structure and Design

Constructed with a welded square tube and steel framework, this machine has a compact structure and an aesthetically pleasing design. The inclusion of high-power gear transformers adds to its robust build.

Advanced Cutting Processes

- Capabilities to cut horizontally, vertically, and in square patterns.

- Equipped with a neutral reset device for precise operations.

- Features three rows of wire drawing for optimal cutting.

Efficiency and Accuracy

The cutting machine offers high efficiency and precision, with reduced spare time of 3-10 minutes. It can cut plate thickness to a minimum of 3mm.

Technical Specifications

- Maximum Cutting Size (mm): DSQ-3000C: 3000*1250*1250, DSQ-4000C: 4000*1250*1250, DSQ-6000C: 6000*1250*1250

- Heating Wires Amount: Cutting Size pcs: 60, Vertical pcs: 60, Portrail pcs: 20

- Working Speed (m/min): 0~2

- Connected Load/Power (kw): 35

- Overall Dimension (L*W*H) mm: DSQ-3000C: 5800*2300*2600, DSQ-4000C: 6800*2300*2600, DSQ-6000C: 8800*2300*2600

- Weight (kg): DSQ-3000C: 2000, DSQ-4000C: 2500, DSQ-6000C: 3000

Application and Benefits

Designed for cutting foam boards with precision, the Type C machine is suitable for straight, bevel, and shaped machining of EPS boards. Its stable guide rails and optimized screw drive structure guarantee cutting accuracy and smoothness. With an energy-saving design, it enhances operational convenience and production stability, improving processing efficiency and minimizing material waste. Whether for building insulation boards, packaging, or custom foam products, this machine ensures high-quality forming and cutting to meet diverse production needs.