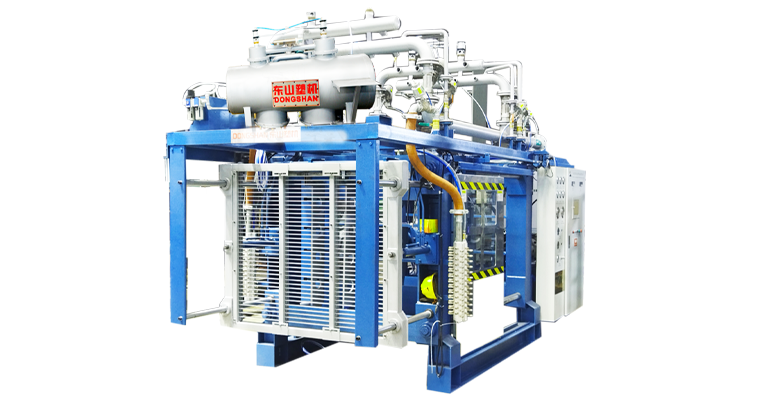

High-Speed EPS Foam Block Molding Machine

Technical Specifications of High-Speed Automatic EPS Foam Forming Machines

Our range of high-speed automatic EPS foam forming machines offers unparalleled efficiency and reliability for processing various foam boards. These machines are designed for ease of operation and stability in output, making them ideal for mass production.

Standard Mould Sizes

- FAV1200: 1200*1050 mm

- FAV1400: 1400*1250 mm

- FAV1750: 1750*1450 mm

- FAV1800: 1800*1600 mm

- FAV2000: 2000*1800 mm

Maximum Product Size

- FAV1200: 1050*900*420 mm

- FAV1400: 1250*1100*420 mm

- FAV1750: 1600*1300*420 mm

- FAV1800: 1650*1450*420 mm

- FAV2000: 1850*1650*420 mm

Key Features

- Striking Mould Range: 150 mm to 1500 mm

- Steam Entry: Ranges from 3-inch (DN80) to 5-inch (DN125) depending on model

- Cooling Water Entry: Ranges from 2.5-inch (DN65) to 5-inch (DN125) depending on model

- Compressed Air Entry: Ranges from 2-inch (DN50) to 3-inch (DN80) depending on model

- Cycle Time: Varies by model, from 50 to 200 seconds

- Connected Load/Power: Ranges from 11 Kw to 20 Kw

- Overall Dimensions and Weight: Specific to each model, providing a range of options for different space requirements

Production Efficiency

Each model offers a unique balance of speed and power, designed to maximize output while ensuring consistent quality. The machines consume minimal resources per cycle, including steam, cooling water, and compressed air, making them both cost-effective and environmentally friendly.

With a focus on enhancing production efficiency, our high-speed automatic EPS foam forming machines are the perfect solution for your manufacturing needs.