Quick Mold Change Machine - Revolutionary Design

Innovative EPS/EPP Rapid Mold Change Machine

Dongshan presents its cutting-edge rapid mold change machine, designed specifically for the efficient production of EPS/EPP foam products. This state-of-the-art equipment significantly reduces mold change time while boosting production efficiency. Trust in Dongshan's precision automated control system for a seamless, reliable, and user-friendly operation.

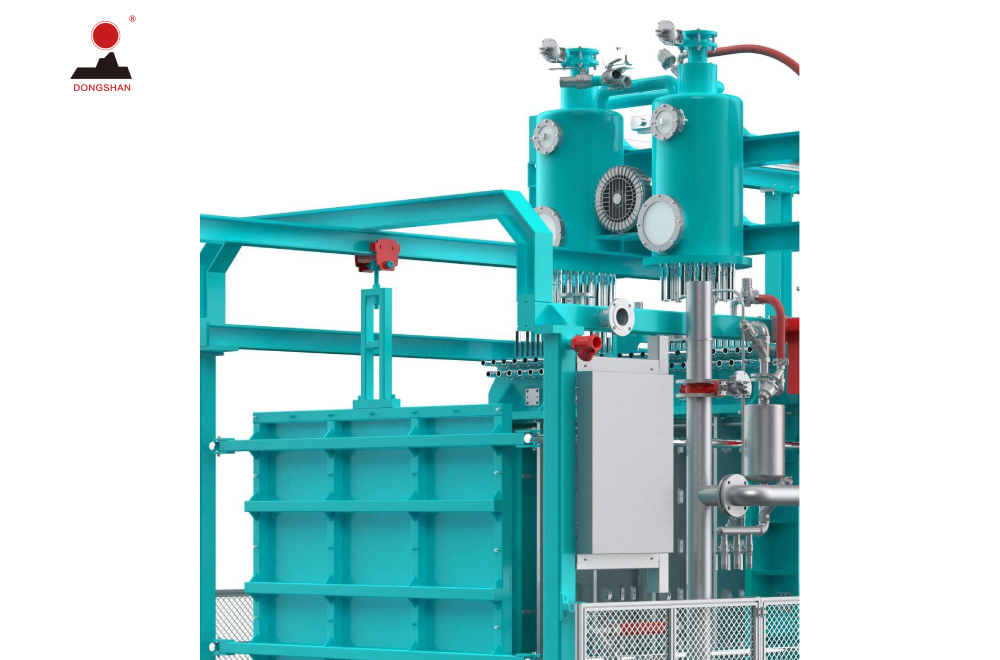

Mechanical Structure and Pipeline System

- Optimized Energy Efficiency: Self-contained insulated mold cavity minimizes heating and demolding heat loss, saving 30% on steam energy.

- Enhanced Production Capability: Horizontal dual-material barrels support dual-density production with feeding, vacuum, and pulse feeding.

- Fast Connection: Stainless-steel quick-plug material gun connector for precise assembly.

- Durable Construction: Mold body made of high-strength steel, beveled and gas-welded, then annealed for durability.

- Robust Design: Features 4 high-frequency quenched 45# steel guide columns with hard-chrome plating.

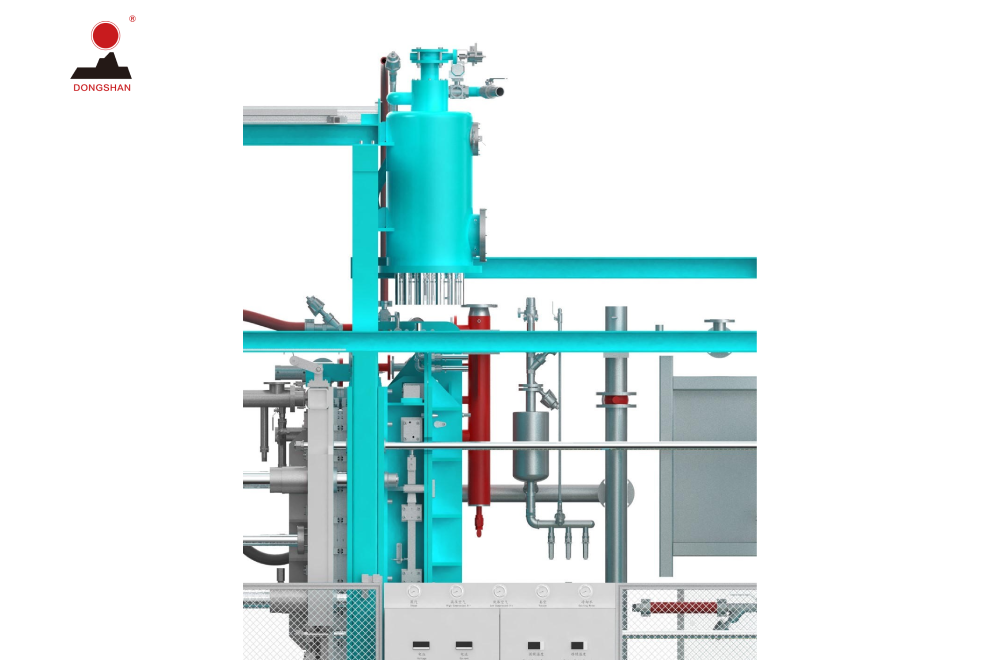

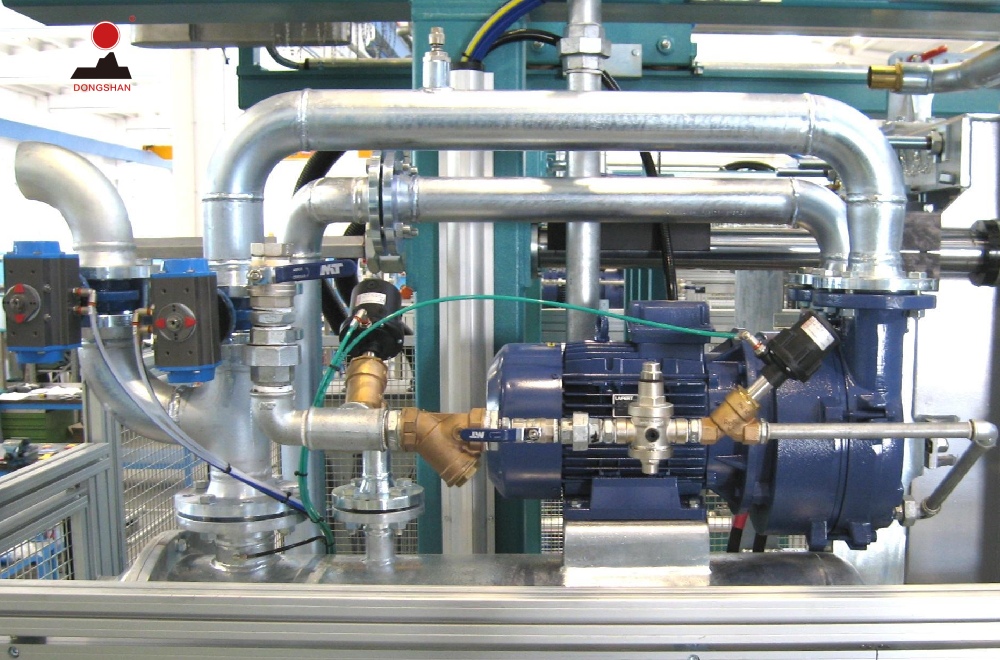

Advanced Hydraulic System

- Controlled Operations: Digital encoder ensures smooth mold stroke transitions.

- Triple Safety Interlocks: Complies with mechanical, hydraulic, and electrical safety standards.

Efficient Steam Heating System

- Stable Performance: Remote-controlled steam valve maintains ±0.2 bar pressure accuracy.

- Proportional Control: Adjust air pressure via touch-screen for steam, demolding, feeding & barrel pressures.

- Energy-Saving Feedback: Single-machine energy recovery enhances vacuum efficiency and decreases power usage by over 50%.

Reliable Electrical Control System

- Real-Time Monitoring: First-tier PLC and touch-screen provide immediate equipment diagnostics with fault alarms and operation protection.

- Quick Mold Change: Features a rapid mold change system to boost productivity.

Technical Specifications

- EPS1070FHS: Max Product Size: 1070×870mm, Dimensions: 6105×2560×4560mm, Molding Time: 45~85s/cycle, Weight: 7.80t

- EPS1270FHS: Max Product Size: 1270×1070mm, Dimensions: 6105×2760×4560mm, Molding Time: 60~120s/cycle, Weight: 11.0t

- EPS1470FHS: Max Product Size: 1470×1270mm, Dimensions: 6105×2960×4760mm, Molding Time: 60~120s/cycle, Weight: 12.5t

- EPS1670FHS: Max Product Size: 1670×1470mm, Dimensions: 6105×3160×4960mm, Molding Time: 60~120s/cycle, Weight: 14.0t

- EPS1870FHS: Max Product Size: 1870×1470mm, Dimensions: 6105×3400×4960mm, Molding Time: 60~120s/cycle, Weight: 15.0t

- EPS1870FHS-B: Max Product Size: 1870×1670mm, Dimensions: 6105×3400×5160mm, Molding Time: 60~120s/cycle, Weight: 16.0t

Choose Dongshan's rapid mold change machine for high stability, energy efficiency, and a cost-effective solution to modern foam processing challenges.