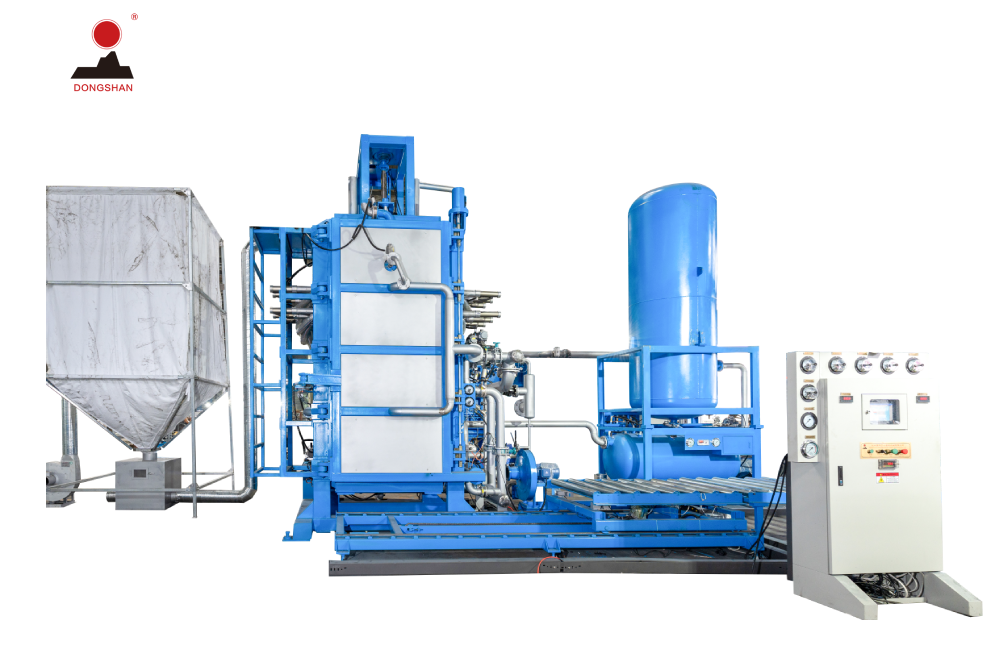

Vertical EPS Block Molding Machine with Vacuum

Innovative Machine Structure for Efficient Production

Our EPS automatic shape moulding machine features a compact design, requiring minimal space while delivering maximum efficiency. With adjustable block sizes and heights, this machine is engineered for flexibility and precision.

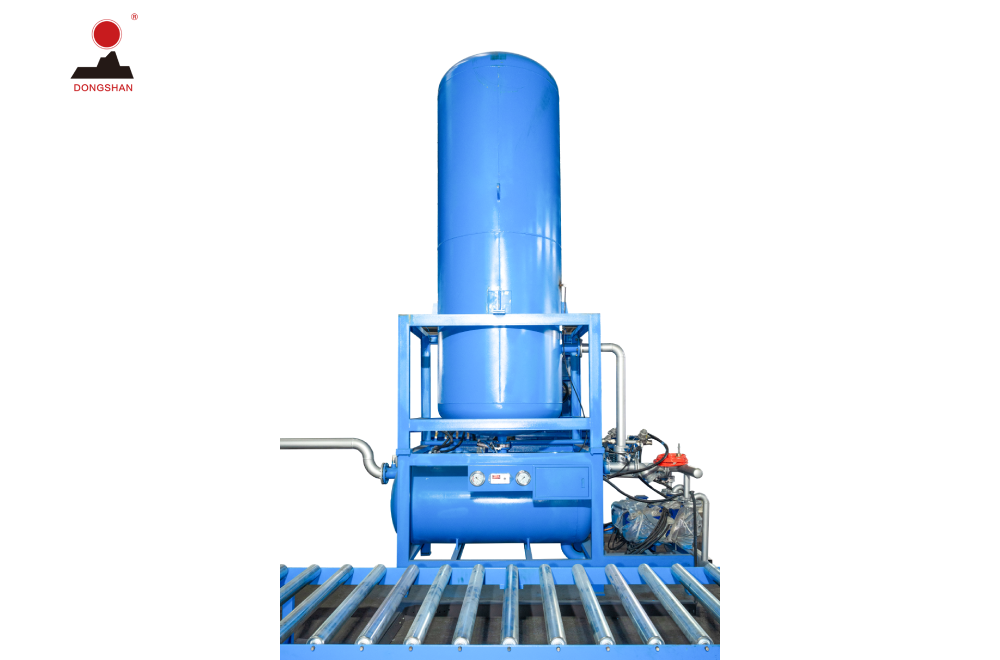

Robust Construction for Enhanced Durability

The machine boasts a high-strength frame with welded polystyrene moulds, reinforced by durable rectangular tubes and steel plates. Each frame undergoes heat treatment to relieve welding stress and prevent deformation, ensuring long-term reliability.

Advanced Surface Treatment for Superior Protection

Post heat-treatment, frames are sandblasted for rust prevention, significantly improving the coating’s anticorrosion performance. This meticulous process guarantees a longer lifespan for each machine component.

State-of-the-Art Safety and Stability

Equipped with three German precision gauges and a safety valve, the block moulding machine has passed rigorous water and steam pressure tests. This ensures both stability and safety during operations.

Efficient Steam and Heating System

The steam system utilizes three ball valves, reducing steam consumption by 20% compared to traditional single-valve systems. Integrated with ISO-standard butterfly valves, the machine achieves remarkable thermal stability and extended service life. The 3-dimensional heating ensures quicker heating times, saving energy.

Intelligent Control System

Featuring an industrial PLC (Mitsubishi) and a user-friendly touch screen (Weinview), the machine is simple to operate. It seamlessly integrates with customer ERP software for streamlined production control. The material level sensor manages the filling process, while a foam pressure sensor monitors the block mould's filling, heating, cooling, and opening stages.

Automatic and Remote Operations

Enjoy fully automated processes with remote control capabilities for timely monitoring and distance support. The machine’s intelligent design also ensures efficient drainage, reducing block moisture content, and maintaining product quality.

Technical Specifications

- Block Mould Cavity Sizes: Varies from 2040x1240x1030 mm to 6080x1240x1030 mm

- Steam Consumption: Ranges from 70-180 kg/cycle across different models

- Compressed Air Consumption: Varies from 1.5 m3/cycle to 4.5 m3/cycle

- Vacuum and Cooling Water Specifications Available

- Cycle Times: From 6 to 12 minutes depending on model

- Connected Load/Power: From 13KW/28KW to 16.5KW/28.5KW

- Dimensions and Weight: Customizable to meet specific needs